NAME Plataforma multidisciplinar de impresión 3D

Plataforma multidisciplinar de impresión 3D: la impresión 3D es una tecnología de fabricación aditiva en el material que se distribuye prediseñado por una capa, para construir un modelo físico 3D que refleje la anatomía del paciente. La nueva Plataforma Multidisciplinar de Impresión 3D (3DPP) del Instituto de Investigación Biodonostia, consta de dos unidades interdependientes: • La «Unidad de Biomodelado 3D», con sede en la OSI Donostialdea, ofrece servicios en el área de biomodelos, creando modelos de la enfermedad (principalmente tumores) para mejorar el abordaje quirúrgico y los tiempos operatorios de los pacientes, así como la personalización de implantes protésicos. Esta unidad cuenta con una Stratasys F730, que permite imprimir con diferentes materiales (PLA3, ABS-M30, ASA, PC-ABS, TPU 92A, material de soporte QSR), para la mayoría de modelos hechos en casa. Esta unidad cuenta también con una estrecha colaboración con Tknika, centro de investigación vasco en educación y formación profesional. Esta colaboración posibilita el diseño de modelos complejos mediante la creación de grupos de trabajo con los perfiles necesarios y la impresión mediante la impresora Stratasys J750 con tecnología PolyJet. • La «Unidad de Biofabricación 3D», ubicada en el segundo piso del Instituto Biodonostia, ofrece servicios en el área de bioimpresión de células y tejidos para su uso en enfoques de medicina regenerativa.

FIELDS OF APPLICATION

Additive manufacturing

Electromedical devices

Orthopedic and rehabilitation Technology

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

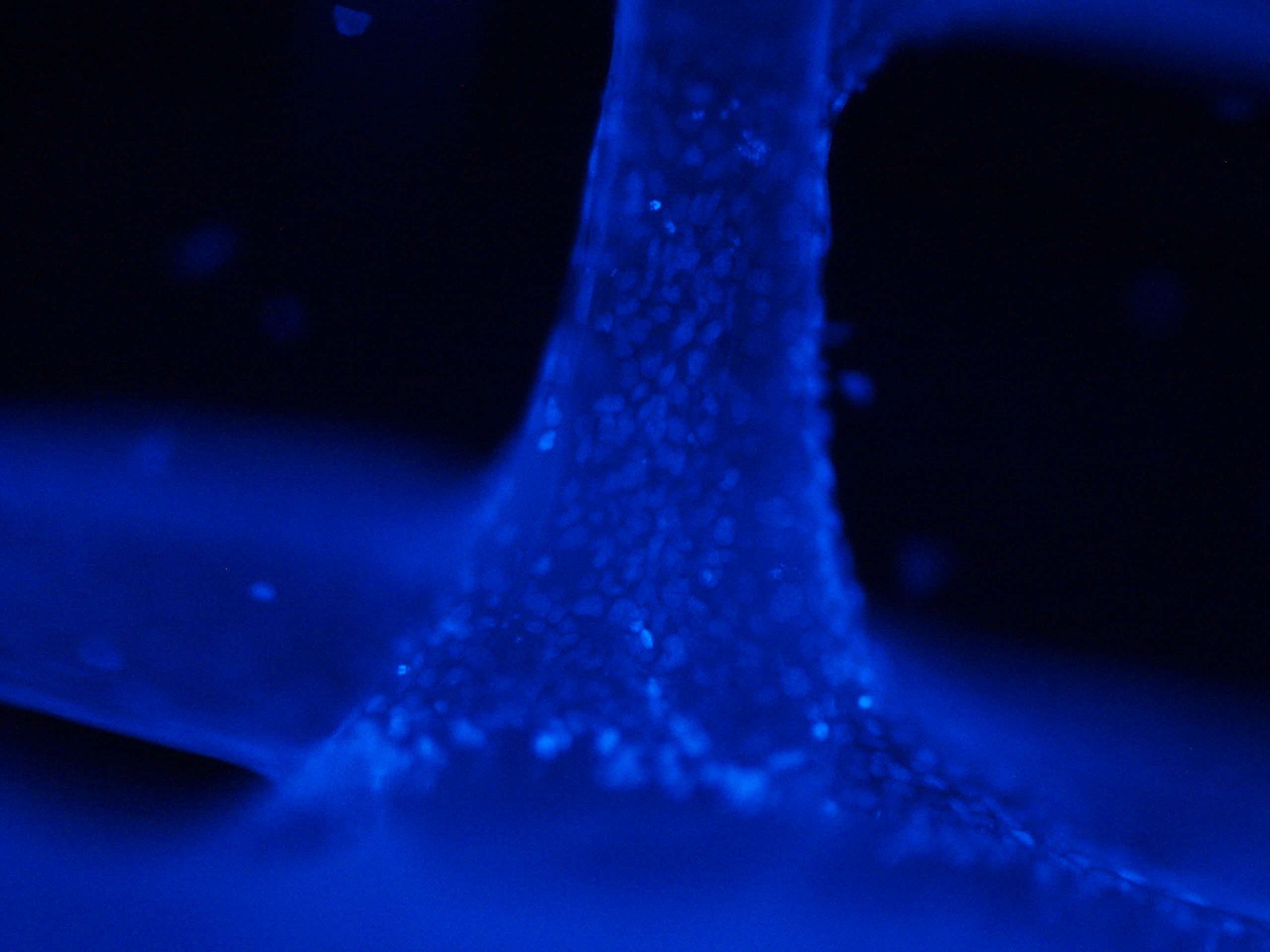

bIDO-I bioprinter

50 µm resolution and 12x12x12 cm volumes printing capacity

-

FDM (Witbox, BQ)

PLA filament printer

-

FDM Biobots-Allevi bioprinter

150 µm resolution and 9x9x9 cm volumes printing capacity

-

Stratasys F730 Printer

SERVICES OFFERED BY THE ASSET

3D Form2 printing

Resin printing

3D Stratasys F370 printing

Several materials printing (PLA3, ABS-M30, ASA, PC-ABS, TPU 92A, QSR)

Biomodel processing

Isopropyl treatment and Sodium Hydroxide treatment

High resolution 3D printing and metals

Using Stratasys J750 printer and Polyjet technology.

Image segmentation and sorting

DICOM archive creation

ENTITY MANAGING THE ASSET

Contact person:

IIS Biodonostia

amaia.delvillar@biodonostia.org