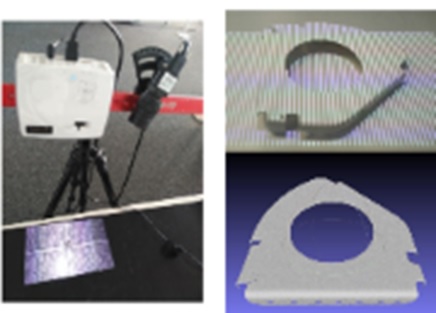

NAME 3D vision system for parts reconstruction, valid for defect detection applications and for location and grasping of parts with flexible robots

The asset is composed by both hardware and software. Regarding the hardware, the asset is composed by distinct industrial 3D vision acquisition devices. The different acquisition systems provide different characteristics in terms of acquisition speed, accuracy, area to inspect, portability and so on, which makes it possible to adapt to the requirements of the application. For defect detection, the software is designed to capture information about the environment of the robot, and send to it the coordinates necessary to grasp a certain object. There is a calibration phase between the 3D vision system, the robot and the gripper. The calibration phase is highly optimized so that minimal manual work is required. The vision software detects a known or unknown object and sends a correction to the robot system so that it can reach the object in an efficient way. The grasping system optimizes the grasping position according to the gripper used and the geometry of the part to be grasped. CAD models of the parts can be used as models for the object detection. For applications of location and grasping of parts with flexible robots, the software is designed to capture information about the environment of the robot, and send to it the coordinates necessary to grasp a certain object. There is a calibration phase between the 3D vision system, the robot and the gripper. The calibration phase is highly optimized so that minimal manual work is required. The vision software detects a known or unknown object and sends a correction to the robot system so that it can reach the object in an efficient way. The grasping system optimizes the grasping position according to the gripper used and the geometry of the part to be grasped. CAD models of the parts can be used as models for the object detection.

FIELDS OF APPLICATION

Advanced manipulation with robots

Flexibility for robotic applications

Manufacture and assembly of components by robots

Quality control with robots

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Custom-made stereovision system based on industrial uEye cameras and a texture projector

-

Halcon vision software libraries

-

In-house developed libraries for calibration, registration, object detection, matching, defect detection, etc

-

Industrial stereovision system ENSENSO

-

Structured light scanner David

SERVICES OFFERED BY THE ASSET

Advanced manipulation using robots

Advanced manipulation using robots

Flexibility for robotized applications

Vision-based parts detection and localization for robot guiding

General services offered by the node agent

1. Technological-economic advice 2. Design, prototyping and validation 3. Training and awareness

Manufacturing and assembly of components using robots

Assembly of components using robots Additive manufacturing using robots Screwing of components using robots

Quality inspection with robots

Dimensional inspection of parts with robots and 3D vision. Integrity control of parts and defect detection using robots and 3D vision.

ENTITY MANAGING THE ASSET

Contact person:

Karmele Florentino

karmele.florentino@tecnalia.com