NAME Fabrikazio gehigarriko robotiko zelula, DED-ARC (WAAM) haridun zuzeneko ezarpen bidezko Ezarpen Tasa Handian oinarritua

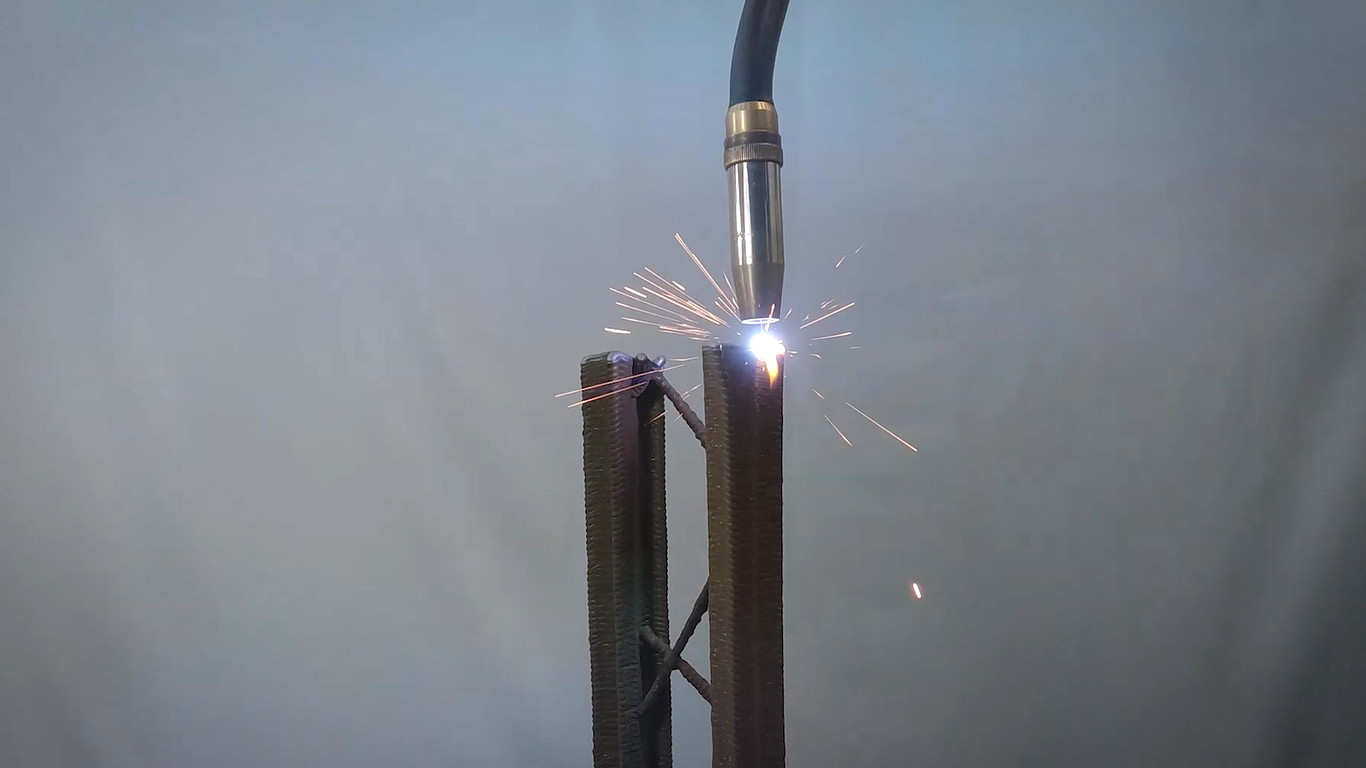

DED-Arc (Directed Energy Deposition-Arc) edo WAAM sistemen eta prozesuen diseinua eta garapena, formatu handiko osagaiak konpontzeko edo fabrikatzeko, fabrikatutako produktuen kalitatea ziurtatzera bideratutako soluzio digitaletan oinarrituta. WAAM prozesu berriak garatzea, uzte-tasa handiagoekin, hari anitzeko teknologiak (adibidez, CMT TWIN) eta hari beroko teknologiak (adibidez, TIGSpeed eta EWM MIG/MAG hot wire) txertatuta. WAAMrako aleazio berriak garatzea. Beharrezko mekanizazio-hazkundeak murrizteko eta fabrikatutako piezen distortsioak minimizatzeko aukera emango duten deposizio-estrategia aurreratuak garatzea. Fabrikazioaren ondoren beharrezkoak diren tratamendu termikoak optimizatzea, propietateen balantze ona lortzeko eta hondar-tentsioak ezabatzeko. Prozesua monitorizatzeko teknologien ikerketa, akats isolatuak goiz detektatzeko (porositateak, fusio-faltak). Akatsak detektatzeko ikuskapen ez-suntsitzaileko teknologietan (ultrasoinuak, erradiografia, tomografia) ikertzea. 2.5D eta 3D piezak automatikoki fabrikatzeko prozesua eta CAD/CAM/CAE tresnak simulatzea.

FIELDS OF APPLICATION

AM Digital Chain.

AM process validation

AM/3D Printing Process

Design for AM and Digital pre-processing

Materials for 3D/AM

Post process

Supporting technologies and processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

CINEMATIC STATIONS

CNC, Robot (KUKA, FANUC, ABB), Gantry and 2-axis positioners and rotary tables.

-

ENERGY SOURCES

CMT, CMT Twin, TIG, plasma, EWM MIG/MAG.

ENTITY MANAGING THE ASSET

Contact person:

Maitane Ipiñazar

mipinazar@lortek.es