NAME FSW

Máquina Gantry adaptable a diferentes procesos de fabricación (FSW, Conformado incremental, WAAM), con siguientes características: • Año de fabricación: 2007 • Nmax: 665 rpm • vrápido: 15 m/min • Esfuerzo axial en eje Z: Max. 20 kN • (XxYxZ) 1800x900x700 mm. • Giro de cabezal: A +/- 20º C: +/- 180º • Precisión en Z: 0,1mm • Control SIEMENS 840D • Cabezal COMBINADO de ejes A+C junto con eje extra W.

FIELDS OF APPLICATION

Advanced forming

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Devices for FSW process

Non-consumable rotating tool with a profiled nipple and a flat cross-section shoulder. Conventional tool for flat joint and special tool for angle joint.

-

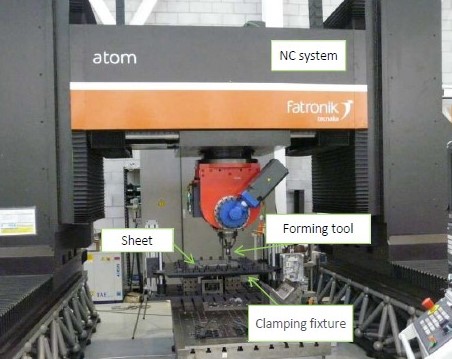

Devices for ISF process

Punch, roller, hot forming furnace and sheet metal clamping tooling

SERVICES OFFERED BY THE ASSET

FSW (Friction Stir Welding) Process

Optimisation of process parameters, Development of devices and control techniques, process monitoring.

Incremental Sheet Forming (ISF)

Optimisation of process, Development of devices (tooling, tools, thermal assistance devices, etc.) and control techniques, development of process models for integration in programming software for AISF processes and design of optimisation strategies, process monitoring.

ENTITY MANAGING THE ASSET

Contact person:

Karmele Florentino

karmele.florentino@tecnalia.com