NAME Plastiko eta konpositeetarako teknologia aditiboak garatzeko zentroa

Zentroak badu nahikoa ahalmen binder edo erretxina termoplastiko berriak garatzeko edo birformulatzeko, honetarako: a) FDM (harizpia edo zuzeneko estrusioa) eta laser sintering bidezko teknologia aditiboen bidez prozesatzeko, edo b) eskakizun berriak betetzeko (mekanikoak, suarekiko erresistentzia, elektrikoak eta abar), zuntz jarraitua erabiliz konpositeen aurreforma lortzeko prozesu aditibo berrietarako, gainazalen propietateak eta propietate mekanikoak hobetzeko postprozesuetarako, moldeak eta tresnak diseinatzeko, funtzio elektrikoak osagai ez-elektrikoetan txertatzeko, eta kontrol-ekipamendu eta -software berriak garatzeko.

FIELDS OF APPLICATION

AM/3D Printing Process

Design for AM and Digital pre-processing

Materials for 3D/AM

Post process

Supporting technologies and processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Additive Manufacturing Unit: Stratasys uPrint SE 3D Printer, TUMAKER Printer, ZORTRAX M200 Printer, EOS - SLS Printer

-

Electronic printing Unit: printing equipment for conductive inks and pastes (injet, screenprinting, laser sintering)

-

Materials development Unit: Extruders for extrusion and co-extrusion and injection, additive dispersion equipment (Calender, mill, Dispermart, baths and ultrasonic tips)

-

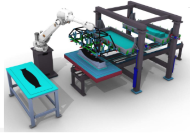

TFP (Tailored Fiber Placement) equipment for the manufacture of preforms by means of TFP or stiching of carbon fibers, glass, aramid, etc.

SERVICES OFFERED BY THE ASSET

Materials development

Reformulation and development of new materials to obtain better or new features with additive processes

Post-process development

Surface and resin infiltration treatments to improve the performance of parts or tools

Process development

Development of Additive Technologies for preforms manufacturing

Product development

Design, topological optimization and validation of components and tools. Electrical/electronic function integration

ENTITY MANAGING THE ASSET

Contact person:

Alfredo Suarez

alfredo.suarez@tecnalia.com