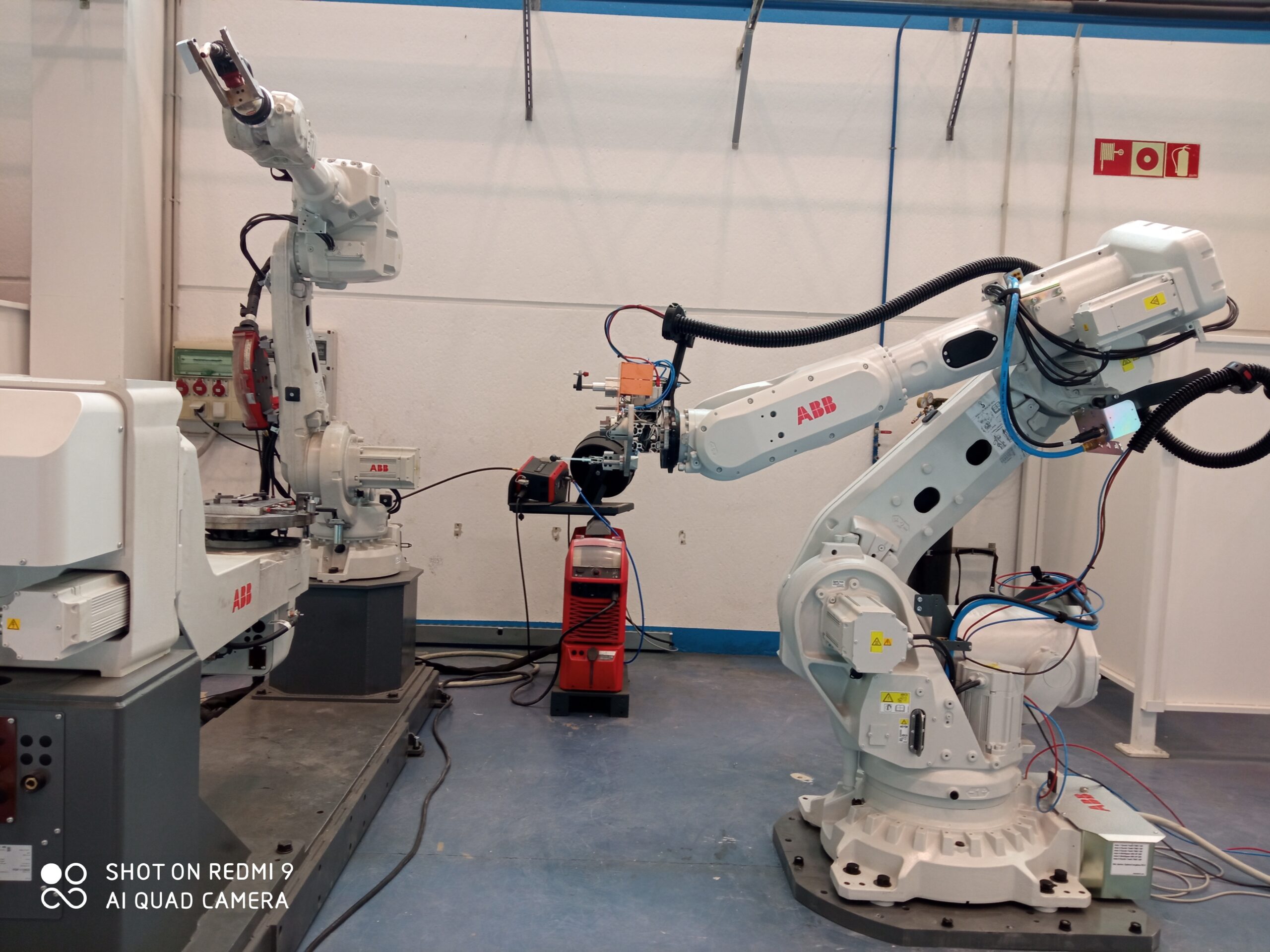

Cooperative robotic unit

DESCRIPTION

Cell of two robots that collaborate, configure and change automatically for each final assembly according to the manufacturing program so that:

-Integrates efficient and safe handling of heavy weldments of various sizes

-Minimize floor space requirements

-Produces consistent welds to improve part quality

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Flexible cell for assembly and additive manufacturing with cooperative robotsCell of two robots that collaborate, configure and change automatically for each final assembly according to the manufacturing program so that:

-Integrates efficient and safe handling of heavy weldments of various sizes

-Minimize floor space requirements

-Produces consistent welds to improve part quality

SERVICES OFFERED BY THE ASSET

Feasibility analysis, parameterization, additive manufacturing, joining and training

ENTITY MANAGING THE ASSET

LORTEK S.C.

Contact person: Eider Gorostegui