NAME Prentsa Isostatiko Beroa – HIP

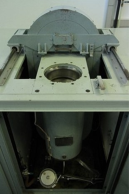

ASEA prentsaren QIH-6 modeloa, 2000 atmosfera (200 MPa) arteko presiora eta 2000 °C arteko tenperaturara hel daiteke grafitozko berogailua badu edo 1450 °C arteko tenperaturara Mo berogailuarekin. Espazio erabilgarria: 110 mm-ko diametroa eta 240 mm-ko altuera. 30 kg arteko lan-karga izan dezake. Lan-atmosfera estandarra Ar izan daiteke, eta, tarteka Nitrogenokoa, grafitozko berogailuarekin. Metalezko harizko bobina bidez aurretentsatutako ontziaren barruko aldea da espazio erabilgarria. Ontzi hori haustura-mekanikaren irizpideei jarraiki diseinatu da, segurtasuna bermatzeko. Esfortzu axialak goiko eta beheko itxituretan kokatu den euskarri-etxeen bidez gainditzen dira. Ekipo hau oso malgua da zikloak, arrapalak eta mantentze-lanak diseinatzeko, dela tenperatura edo dela presio ezberdinetarako, eta porositatea ixteko zein tratamendu termikoetarako erabiltzen da, ekoizpen-prozesuak sinplifikatzeko.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

ASEA QIH6 HIP unit

-

Connection to the internal network

SERVICES OFFERED BY THE ASSET

HIP to improve the properties of components produced by AM

HIP is present in the AM value chain as a post-process (as a next step to the 3D printing). The main function is the improvement of the mechanical behavior of the parts healing defects (pores, cracks do not connected with the surface of the parts, segregation, columnar structure …). The improvement in properties are also associated to a decrease in the deviation obtained as well the residual stresses. It also allows (depending of the cooling capacity) the reduction of the process steps simplifying heat treatments.

Process parameters optimization

Determination of the optimum HIP parameters in order to improve the mechanical behaviour. This service includes tests at different Pressures, temperatures, times, chemical composition, mechanical and microstructural characterization.

Production of prototypes and demonstrators

Post-processing in AM: HIPping of AM prototypes and demonstrators

Technical feasibility studies.

Validate the technical and economic feasibility of the production of parts by AM+HIP

ENTITY MANAGING THE ASSET

Contact person:

Iñigo Iturriza Zubillaga

iiturriza@ceit.es