NAME Oso kognitiboak diren ekoizpen-plantetarako hiperkonektatutako arkitektura

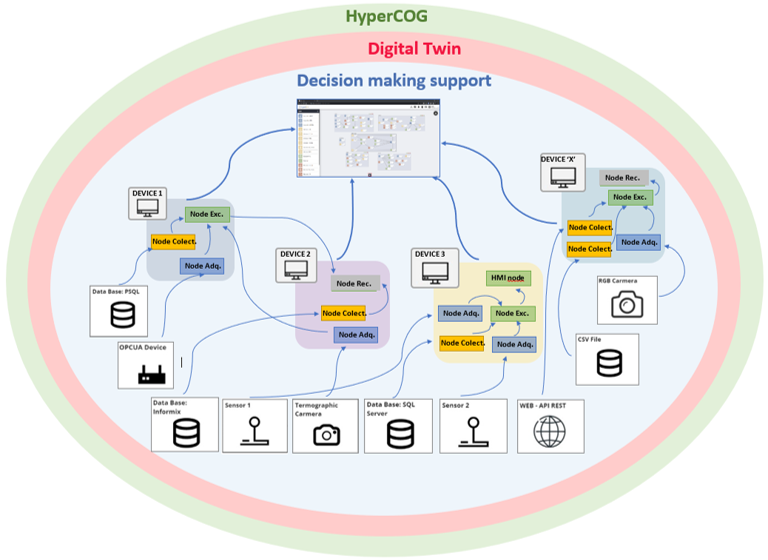

Aktibo logiko honek prozesu-industriaren eraldaketa digital osoa lortu nahi du, oso kognitiboak diren ekoizpen-instalazioetarako (HyperCOG) arkitektura hiperkonektatuan oinarritutako sistema ziber-fisikoa ezarriz. Horri esker, fabrikazio-ingurune malguak eta baldintza aldakorretara egokitzeko gai direnak sor daitezke, teknologia aurreratuak eta erabakiak hartzen laguntzeko sistemak erabiliz, prozesuaren datuak denbora errealean erabiliz. Horregatik, teknologia disruptiboak integratuz, hala nola sentsorika kognitiboa, datuen analitika aurreratua, gauzen internet edo adimen artifiziala, HyperCOG, produkzio-prozesuaren biki digital bat lortzen du, komunikazio-egitura klasikoa hausten duten nodo digitalen sare hiperkonektatu baten bidez. Horrela, errendimendu handiko gaitasun informatikoak erabiliz, HyperCOGek sendotasuna eskaintzen dio prozesuen industriari, egoera desberdin eta zalantzagarrietan.

FIELDS OF APPLICATION

Digitalization and Conectivity

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Cyber-physical system architecture

Cyber-physical architecture based on a hyperconnected network of digital nodes

-

Processing and storage units

Equipment capable of executing advanced algorithms and storing data locally or in the cloud.

-

Sensory and digital devices

Relevant information sources of the process

SERVICES OFFERED BY THE ASSET

Digitization of industrial processes

Implementation, configuration and monitoring of the cyber-physical system in industrial environments of different sectors.

Frogatzailea

Demonstrator of the cyber-physical system developed for the welding process

ENTITY MANAGING THE ASSET

Contact person:

Maitane Ipiñazar

mipinazar@lortek.es