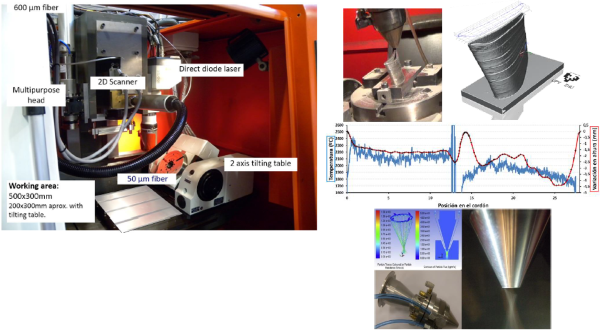

NAME Laser Cladding bidezko fabrikazio gehigarrirako LMD sistema Aktinos 500

5 ardatzeko laser cladding sistema 600x400x400 mm-ko lan bolumenarekin eta B± 110º eta C 360º ardatz errotabibo gaitasunarekin -kW 1 -eko fibra laserra 2 garraio fibrekin 100 eta 600 mikrakoak - Fagor 8070C etheret-era konektaturiko CNC-a eta urrunezko karga eta monitorizazio aukerarekin -Laser ekarpen prosezurako barneraturiko monitorizazio sistemak: tenperatura pirometroaz, ekarpenaren altuera laser track baten bidez eta melt pool-a AV kamera bitartez -Ibilbide konplexuaren programazioa aukera/5 ardatzean Siemens NX API baten bitartez

FIELDS OF APPLICATION

AM process validation

AM/3D Printing Process

Design for AM and Digital pre-processing

Materials for 3D/AM

Post process

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Aktinos 500 LMD system

SERVICES OFFERED BY THE ASSET

Adaptation of laser additive systems in situ

Laser cladding nozzle design, advice on laser additive set-up configuration, design and equipment specifications

Adaptation of laser additive systems in situ

LMD process comparison with other AM processes: Mechanical properties characterization, metallurgical structure, process capabilities, requirements, etc.

Advanced Training in LMD

Customized training in LMD technology, applications, equipment, programming, strategies, powder handling and recycling.

LMD Additive Manufacturing (AM):

Complex part manufacturing by LMD in different materials

Part coating by laser cladding

Improvement of tribological properties on complex parts by laser cladding (friction, wearing, thermal…) of ceramic materials

Part repair by LMD

Improvement of tribological properties on complex parts by laser cladding (friction, wearing, thermal…) of ceramic materials

ENTITY MANAGING THE ASSET

Contact person:

Aitzol Lamikiz Mentxaka

aitzol.lamikiz@ehu.eus