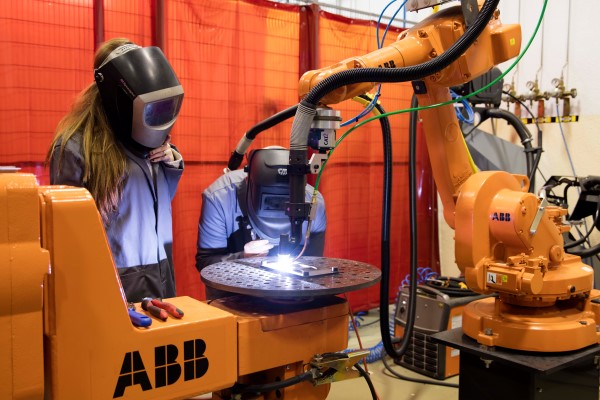

NAME Metal-eranskineko zelula (ABBko IRB-1600 ABB robota) eta SBIko plasma-soldadurako makina (PMI-280B)

Plasma-soldadurako prozesu bidezko eta hari-ekarpeneko metal-eranskineko zelula, bi ardatzeko posizionatzailea duen ABBko robot batean, pieza berriak sortzeko, balio erantsi handiko osagaiak konpontzeko eta oinarrizko piezetan geometria gehitzeko. Zelula kanpoko ingurunetik isolatuta dago, pertsonen segurtasuna bermatze aldera. Robotaren bidez, material-eranskineko ibilbideak CAM PowerMill softwarearen bidez programatzen dira.

FIELDS OF APPLICATION

AM process validation

AM/3D Printing Process

Design for AM and Digital pre-processing

Materials for 3D/AM

Post process

Supporting technologies and processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

ABB IRB 6600 industrial robot and IRC5 control device

-

AbiPlas-250 plasma welding torch 2016

-

IRBP-250 two-axis positioning mechanism

-

Plasma welding machine with wire filler (SBI - PMI-280B model)

SERVICES OFFERED BY THE ASSET

Disseminating technology through technical or general conferences

Disseminate additive manufacturing technology as a whole (process, machines, capacities, markets, etc.) holding theoretical-practical workshops, with the asset itself as a work tool.

Process innovation for AM and technical-economic feasibility study of processes

Analysis and technical-economic validation of alternative manufacturing processes to the current ones, such as additive manufacturing, both for making and repairing parts, as well as for geometric modification of existing parts. The service is developed jointly with the customer.

Search for suppliers for part production using additive manufacturing

After defining the industrialisation process, either using only AM technology or merged with other processes, search for suppliers for series production.

Specific training addressed at Vocational Training teachers

A set of educational activities related to Additive Manufacturing technology aimed at improving competences of teachers. The asset is the basic training tool.

Specific training for company technicians through job training

Training related to Additive Manufacturing technology aimed at technicians from companies that do currently not have the technology, and merging this technology in their production processes would bring them a competitive advantage, or at companies that already work with this technology.

Studies of industrialisation, first series and interdependence with other processes - Study of the industrialisation of a new part reference or redesigned part using additive manufacturing technology. - Integration of additive manufacturing processes in the productive chains, merging them with the current processes. - Product developers - Machinery and equipment manufacturers - Parts manufacturers - Suppliers of finished parts NO

- Study of the industrialisation of a new part reference or redesigned part using additive manufacturing technology. - Integration of additive manufacturing processes in the productive chains, merging them with the current processes.

ENTITY MANAGING THE ASSET

Contact person:

Xabier Cearsolo Aramberri

cearsolo@imh.eus