NAME Fabrikazio gehigarri malgua robotikoa eta material anitzeko kartesiarra, DED-LB laser hautsa zuzenean jalkitzeagatik (LMD)

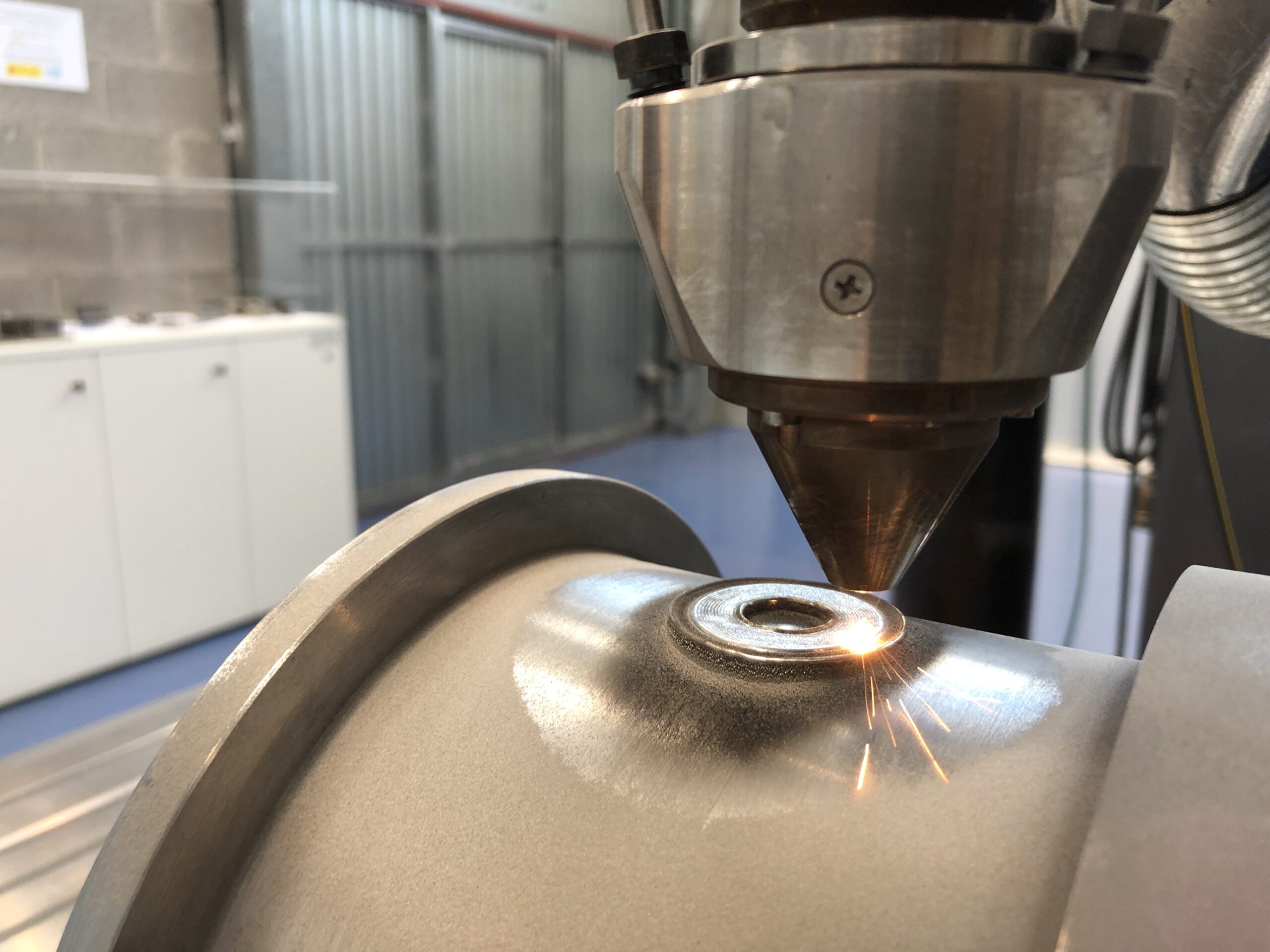

Directed Energy Deposition-Laser Beam, edo LMD, makina malguaren arkitektura desberdinetan material berriak, prozesua, monitorizazioa, kontrola eta simulazioa garatzeko, industriarako konponketa- eta fabrikazio-soluzioak eskaintzeko helburuarekin: - Hauts metalikoa zuzenean jalkiz fabrikatzea eta laser sorta baten bidez galdatzea. - Prozesamendu-parametroak optimizatzea. - Fe, Co, Al edo Ni oinarriko aleazio berriak tenperatura altuko aplikazioetarako eta/edo higadurarekiko eta neke mekanikoarekiko erresistenteak direnentzat. - Serie laburrak, pieza pertsonalizatuak. Balio handiko piezak konpontzea. - Aldagai anitzeko kontrol-prozesuen estrategiak inplementatzea. - Soluzioak eta osagaiak funtzionaltasun berriekin garatzea: diseinu eraginkorragoak, material anitzekoak, propietateen gradienteak dituzten osagaiak, etab. - Industria-produkzioko DED prozesuak digitalizatzea.

FIELDS OF APPLICATION

AM Digital Chain.

AM process validation

AM/3D Printing Process

Design for AM and Digital pre-processing

Materials for 3D/AM

Post process

Supporting technologies and processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

KINEMATIC STATIONS

CNC Fagor 8070

Robot (KUKA, FANUC, ABB)

Gantry

2-axis positioners

Rotating tables -

LASER SOURCES

Disk, Diode, Nd:YAG and Fiber laser sources (up to 6kW) fiber guided

Different optical heads: Trumpf BEO-D70-0º, BEO-D70-90º, BEO-D70M (Spot Laser 1-4mm)

Coaxial and discrete nozzles: COAX40; COAX50, HigNo4.0 y discrete 3-Jet

ENTITY MANAGING THE ASSET

Contact person:

Maitane Ipiñazar

mipinazar@lortek.es