NAME Osagai metalikoen laser bidezko urruneko zein gertuko soldadurarako gelaxka robotikoa

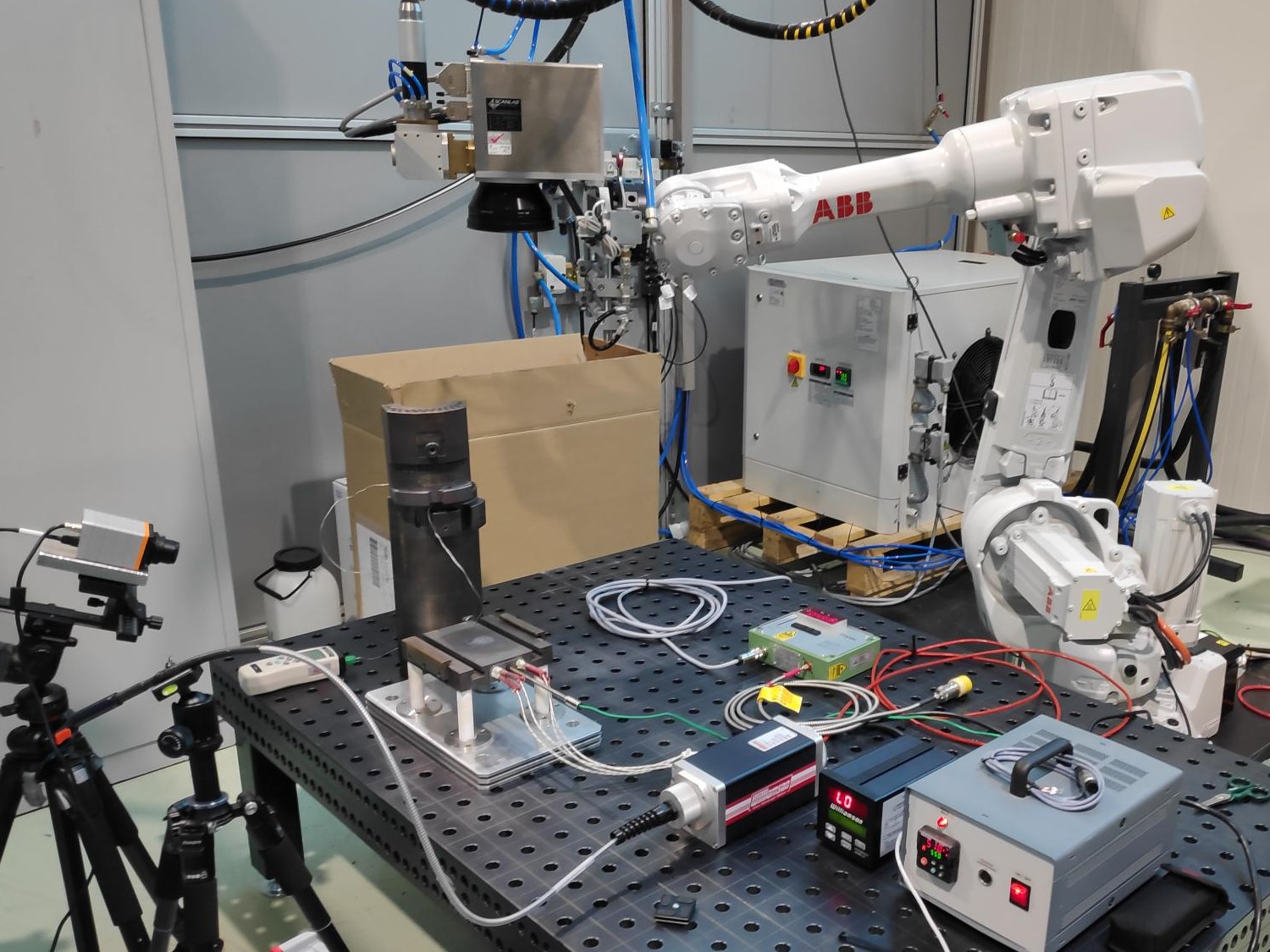

6 askatasun-graduko gelaxka robotikoa, doitasun absolutuarekin eta potentzia eta izpi-kalitate altuko “single mode” motako laserrarekin, osagai metalikoen “wobbling” bidezko urruneko soldadura edo gas bidezko hurbileko soldadurarako. Kontrol-sistemak bi estrategien erabilera txandakatzeko aukera ematen du, bai eta ardatz mekanikoak eta ispiluzko sistema optikoak sinkronizatzeko ere. Soluzioak ikusmen artifizialezko sistema bat dauka, prozesurako ibilbideen definizioan laguntzeko

FIELDS OF APPLICATION

Advanced unions

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Control and monitoring system

Control system with synchronisation of mechanical and optical degrees of freedom.

Vision system for component digitisation and generation of process paths -

Laser source

Cw single mode laser source up to 1.5kW of average power

-

Mirror head

Mirror head for remote processing

-

Robot

Robot with 6 degrees of freedom (gdl) robot with absolute precision

-

Welding head

Fixed optics welding head with gas supply

SERVICES OFFERED BY THE ASSET

Demonstration / Training / Evaluation

Laser base welding demonstrations , training and evaluation

Process development - Conventional laser welding

Process development using conventional laser welding: Laser conduction and key-hole welding

Process development - Remote welding

Process development of remote welding of reflective materials (aluminium, copper, etc.)

ENTITY MANAGING THE ASSET

Contact person:

Javier Arzamendi Manterola

javier.arzamendi@tekniker.es