NAME UV bidezko lehorketako konpositeen fabrikazioan ikerktzeko zelula

Beira zuntzezko konpositeak fabrikatzeko zelula automatizatua, beira zuntzezko era guztietako ehunen bobinak (MAT, Combi eta woven) abiapuntu hartuta eta izpi ultramorez (UV) lehortzeko teknologian oinarrituta. Zelulak UV aurreinpregnatuen fabrikaziorako prototipo bat dauka, hainbat prozesurekin, hala nola inpregnazioa, dosifikazioa eta aurrelehorketa, eta bigarren prototipo bat ere badauka, bukaerako konpositea trinkotzeko eta lehortzeko. Bigarren prototipo horrek buru trinkotzaile bat dauka, robot batek eraginda. Zelula osatzeko, prozesua monitorizatzeko beharrezkoa den ekipamendu bat dauka, zeinarekin indarrak, tenperaturak eta lehortze gradua neurtu baitaitezke, materialaren propietate dielektrikoak neurtuz (DEA analisia). Zelula horrek, halaber, bukaerako konpositeak ezaugarritzea aurreikusten du, hauek neurtuta: porositatea ultrasoinuen bitartez, lodierak, eta zuntz edukiak pirolisiaren bitartez.

FIELDS OF APPLICATION

Design and development of materials

Manufacturing processes

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

DEA analysis equipment. Epsilon 288 from NETZSCH

This equipment is capable of making measurements of the dielectric properties of a liquid material while curing occurs. The evolution of these dielectric properties allows us to monitorize the degree of curing in the process, critical parameter in the productive processes of polymeric composites.

-

NDT equipment

UT inspection tools: single-element transducers and Phased Array transducers, Olympus Focus PX acquisition system.

-

Pirolitic oven

Ovenfor analysis of fiber content by pyrolysis

-

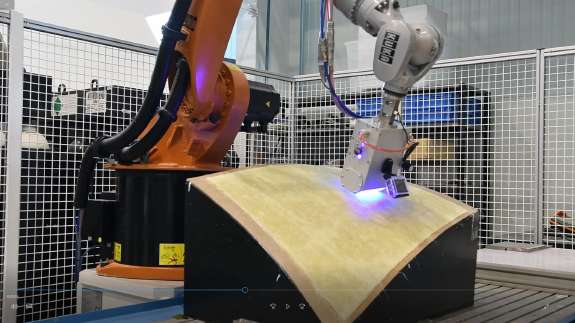

Uv curing glass fiber composites compaction and curing equipment

Prototype consisting of a head actuated by a robot. With this prototype the consolidation stage of the final composite is studied by applying UV light and pressure simultaneously.

-

UV curing prepregs manufacturing prototype

The processes of manufacturing prepreps with UV resins is researched in this prototipe. The process is composed by three stages, impregnation, dosage and precuring.

SERVICES OFFERED BY THE ASSET

Characterization of porosity, thickness and fiber content

The porosity, thickness and the fiber contentof a composite final part are analyzed.

Complete development of composite piece manufacturing using a new process based on UV technology.

From piece geometry, necessary materials and final application, viability of manufacturing processes of UV prepregs, compaction, curing and characterization.

Degree of curing monitoring by DEA

The curing process is monitored for a specific liquid molding process.

ENTITY MANAGING THE ASSET

Contact person:

Javier Vallejo

fjvallejo@ideko.es