DENOMINACIÓN Banco de ensayos para medida de soldabilidad de materiales metálicos con tecnologías de fusión de material para procesos de soldadura con fusión (procesos al arco, soldadura láser, y/o soldadura por haz de electrones)

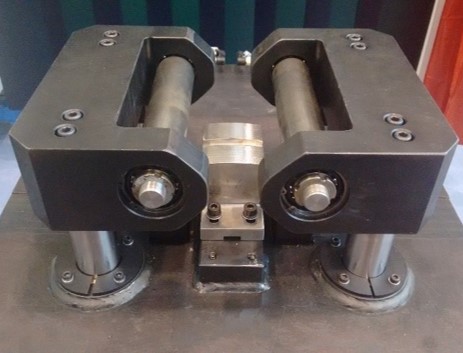

The test bench for weldability evaluation of metallic materials analyses hot cracking susceptibility during welding (fusion welding processes: arc, laser..). The test consists in the application of a bending deformation during welding. Different strain levels are applied by interchangeable die blocks to evaluate the solidification and HAZ liquation cracking susceptibility of the material along the length of the weld. Promoted cracks are measured by LOM. The total crack length (TCL) is related to the susceptibility to hot cracking. The test bench was designed and manufactured by IK4-LORTEK and it complies with the general requirements set by ISO/TR 17641-3 “Destructive tests on welds in metallic materials-Hot cracking tests for weldments-Arc welding processes-Part 3: Externally loaded tests”. The system works both with arc welding and laser beam welding equipment and different testing parameters (stroke rate, welding rate, synchronization set-ups…) can be selected. The Varestraint system integrates a compact tooling for application of bending deformation during test. It is composed by a mandrel and two rolls which rotate without restraint. The Varestraint test bench at IK4-LORTEK is also composed by a hydraulic system controlled by a high precision servovalve to perform an accurate movement of the cylinder. The hydraulic system has been designed to ensure the required force, dynamics and repeatability in terms of stroke rates. Concerning the mechanical components designed by IK4-LORTEK, these comprise: - Support bench or stand - Hydraulic cylinder with linear transductor (5 Ton maximum load, 50 mm maximum stroke) - Die blocks with different radius (160, 80, 40, 27 and 20 mm) - Sample positioning and clamping system (compact tooling) composed by two rotating rollers contacting with support plates.

ÁMBITOS DE APLICACIÓN

Diseño y desarrollo de materiales

Procesos de fabricación

Uniones avanzadas

EQUIPOS Y COMPONENTES MÁS DESTACADOS

-

Banco de ensayos para análisis de soldabilidad

Varestraint test bench, equipped with:

- Main Control cabinet (main experimental parameters control: strain, time...)

- Different equipment for motion: ABB robot, robot ASEA IRB 2000, Robots FANUC 1 and FANUC 2 and a large KUKA gantry

- Different energy sources: laser (Disco laser 5kW, Laser Nd-YAG 3 kW, diode laser 3kW, fiber laser IPG 1kW) or electric arc (processes: PAW, TIG, MIG/MAG)

SERVICIOS OFRECIDOS POR EL ACTIVO

Analysis of the improvement of weldability

This service allows the development of alloys or variations of existing alloys including the previous transformation process (meaning variations in the microstructure) for the study of the improvement of the weldability.

Analysis of the weldability of materials manufactured with different routes

This service allows the validity of the materials for their weldability. This means that it allows the analysis of how the material will behave during the welding processes, evaluating it in a weldability scale.

Analysis of the weldability of materials treated in different conditions

This service allows the analysis of a heat treatment applied to a material for its weldability. It allows the analysis of how the thermal history (melting, solidification, cooling, …) affects to the weldability of a material.

ENTIDAD QUE GESTIONA EL ACTIVO

Persona de contacto:

NIEVES RODRÍGUEZ

nrodriguez@lortek.es