Multidisciplinary platform for the smart manufacturing and monitoring of materials

DESCRIPTION

In this asset, a series of home-designed and made lab equipment and sensors, and the knowledge of several disciplines are integrated. This enables to develop the next aspects:

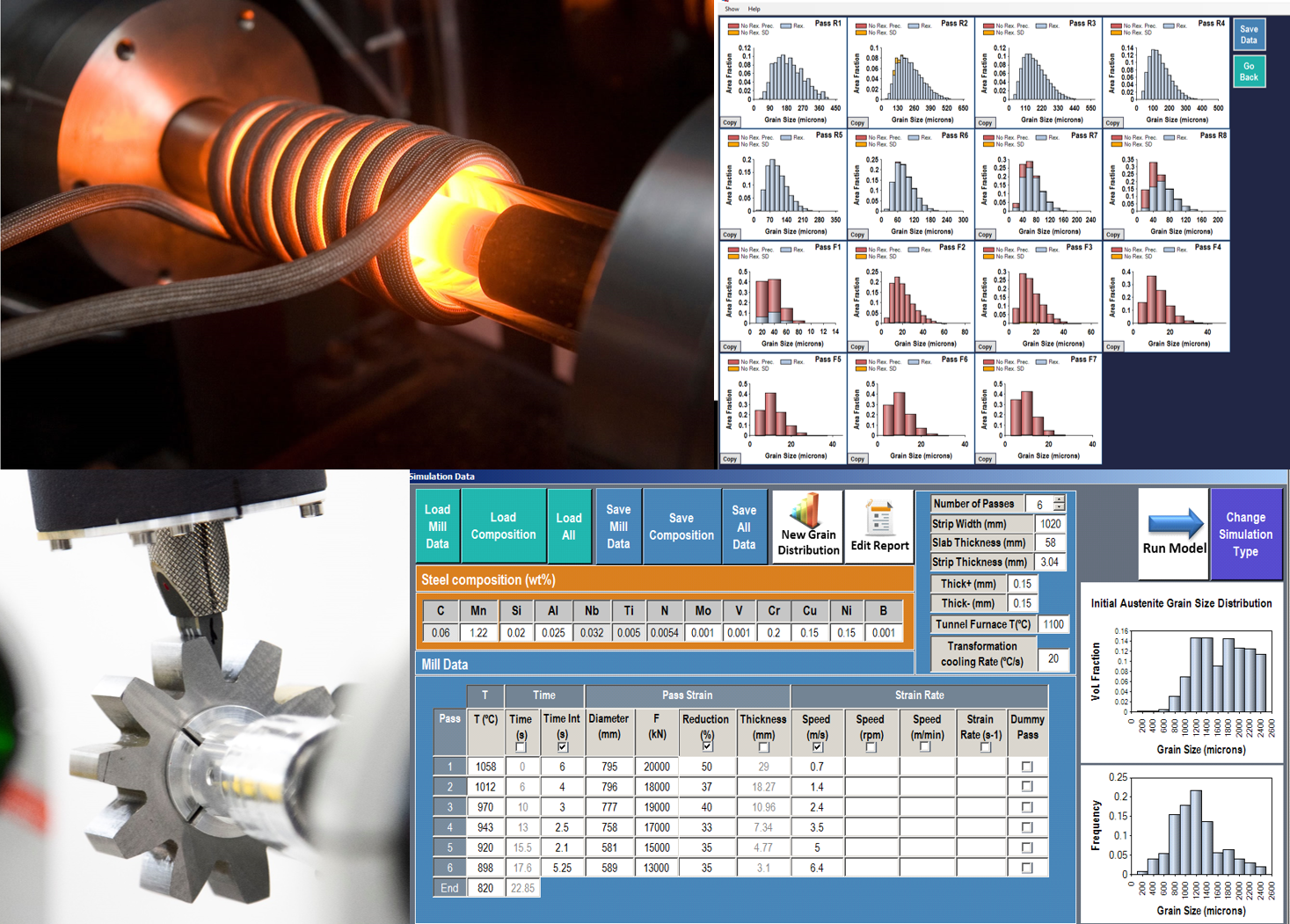

• Modelling of materials and processes

• Monitoring of the material through NDT-electromagnetic techniques and correlation of the signals with its state

• ICT applied to the monitoring of materials

• Data processing and management to control and optimize the process

The objectives are to provide the tools for diagnosis of the strategies to improve the materials and to implement more efficient and safer quality control systems.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Commercial softwareFinite elements, thermodynamic/kinetic calculation programs and home-made models for materials and processes

Conventional and induction thermal treatment laboratory

Torsion test machine that allows simulating multipass thermo-mechanical sequences and cooling conditions

Metallurgical models for steel transformation processes

NDT sensors developed in Ceit-IK4 based in electromagnetic techniques

SERVICES OFFERED BY THE ASSET

Hybrid models for the material and process

Material monitoring

Metallurgical models of the material

Simulations of the thermo-mechanical processes

ENTITY MANAGING THE ASSET

CEIT

Contact person: Denis Jorge Badiola