NAME Korrosioa aztertu eta ebaluatzeko ekipamendua/teknikak/metodologiak

Behar bezalaka ekipatutako instalazioak daude, eta haietan honakoak aurki daitezke: - Ganbara klimatikoak korrosio azeleratuko probak egiteko, tenperatura eta hezetasuna kontrolatuz. Elektrolito agresibo bat erabili ohi da (kloruroa oinarri dutenak, pH desberdinetan), agente oxidatzaileekin eta agente oxidatzailerik gabe (adibidez, kobre-ioiak). - Korrosio elektrokimikoko pilak, intereseko sistema bat elektrolito agresibo baten eraginpean jartzeko (azidikoa, basikoa, kloruroa, fluoruroa, etab.). Mota desberdineko pilak erabil daitezke: arrailduren kontrakoa, tenperatura kontrolatzeko pila, pila horizontal laua, ingurunea kontrolatzeko pila, etab. - Potentziostatoak korronte alternoarekin eta korronte zuzenarekin, hainbat teknika elektrokimiko egiteko, bitarteko/elektrolito jakin batean higatzeko behar den erresistentzia edo marruskadura zinetikoa zehazteko. - Laneko estazio elektrokimikoa, korrosio lokalizatua lortzeko eroankortasun baxuko elektrolito bat ingurune agresibo gisa erabiliz LEIS, SVET eta ac/ic-SECM tekniketarako. - SPK korrosio lokalizaturako; elektrolitoaren presentzia aukerazkoa da - Korrosio-pila batekin egokitutako tribometroa, tribokorrosio-probak egiteko.

FIELDS OF APPLICATION

Coatings and Surfaces solutions

Design and development of materials

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

AC/DC-Potentiostats

AC/DC-Potentiostats to perform Pontentio/Galvano - static/dynamic perturbation as voltammetry, polarization curves, etc. and measurements at open circuit potential like electrochemical noise, impedance, etc. Several electrochemical cells with different features are available to be used.

Acquired during several years (most recent one 2017) -

Climatic chambers for accelerated corrosion

Climatic chambers for accelerated corrosion using chloride based solutions were either saturated humidity and/or aggressive environment based on chloride with and without: acidic pH, cupric ions.

Year of acquisition: 2018 -

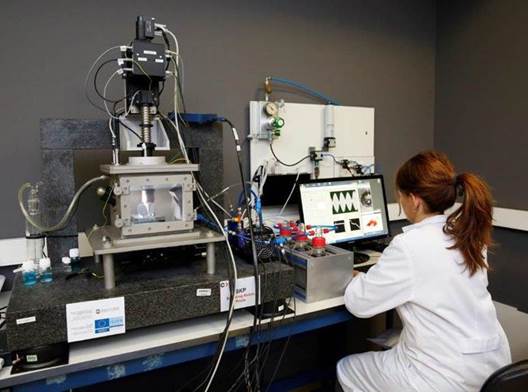

Electrochemical working station for localized corrosion (LEIS, SVET, ac/ic-SECM)

Electrochemical working station for localized corrosion (LEIS, SVET, ac/ic-SECM) using a low conductivity electrolyte with a resolution in the micrometer range:

o LEIS is a scanning technique that combines information of the impedance at localised scale with time-constant resolved signals of conventional EIS to obtain impedance maps of the surface.

o SVET is a scanning technique measuring the potential gradients in the electrolyte (using a fine tipped vibrating microelectrode) due to the presence of anodic and cathodic areas on a surface (corrosion process).

o ac/ic-SECM is a scanned probe microscopy technique in which the electrochemical response of a mobile ultra-microelectrode (UME) tip is used to measure the electrochemical activity of the surface obtaining information like topography, specific elctrochemical reactions (recognizing active/passive regions).

Year of acquisition: 2015 -

Scanning kelving probe SKP

SKP is a non-contact and nondestructive technique able to measure the work function difference between a sample and a reference probe using the vibration condenser method. It can be calibrated to obtain corrosion potential maps of the surface of conductive and semi-conductive materials. The topography can be obtained simultaneously.

Year of acquisition: 2015 -

Tribometer

Tribometer adapted with a corrosion cell to perform tribocorrosion tests in order to explore the degradation and synergy of wear and corrosion phenomena, simultaneously. Year of acquisition: 2015

SERVICES OFFERED BY THE ASSET

Climatic chambers for accelerated corrosion tests (neutral salt spray (NSS), cupric-acetic salt spray (CASS)). Conventional and localized electrochemical techniques for corrosion evaluation.

- Accelerated corrosion tests to evaluate the tendency of materials to be corroded. - Potentio-/Galvano- dynamic/static test of isolated materials or under galvanic coupling (anodic and cathodic branches together or separately) to study the corrosion kinetic. - Water uptake measurements of the coating-metal interface by electrochemical impedance spectroscopy (EIS). - Delamination phenomenon (e.g. cathodic delamination on steel or filiform corrosion on aluminium) monitored by scanning kelvin probe (SKP) using specific configuration. - Customer type: Any type in general, including product developers, parts manufacturers, and finished piece suppliers - Various sectors: Most of the sectors like aeronautics, automotive, biomedical, machine tool etc.

ENTITY MANAGING THE ASSET

Contact person:

Patricia López Ruiz

plopez@cidetec.es