NAME Generador y almacenador de huellas digitales de máquina y HMI personalizados y multicontrol integrables en el control de la máquina.

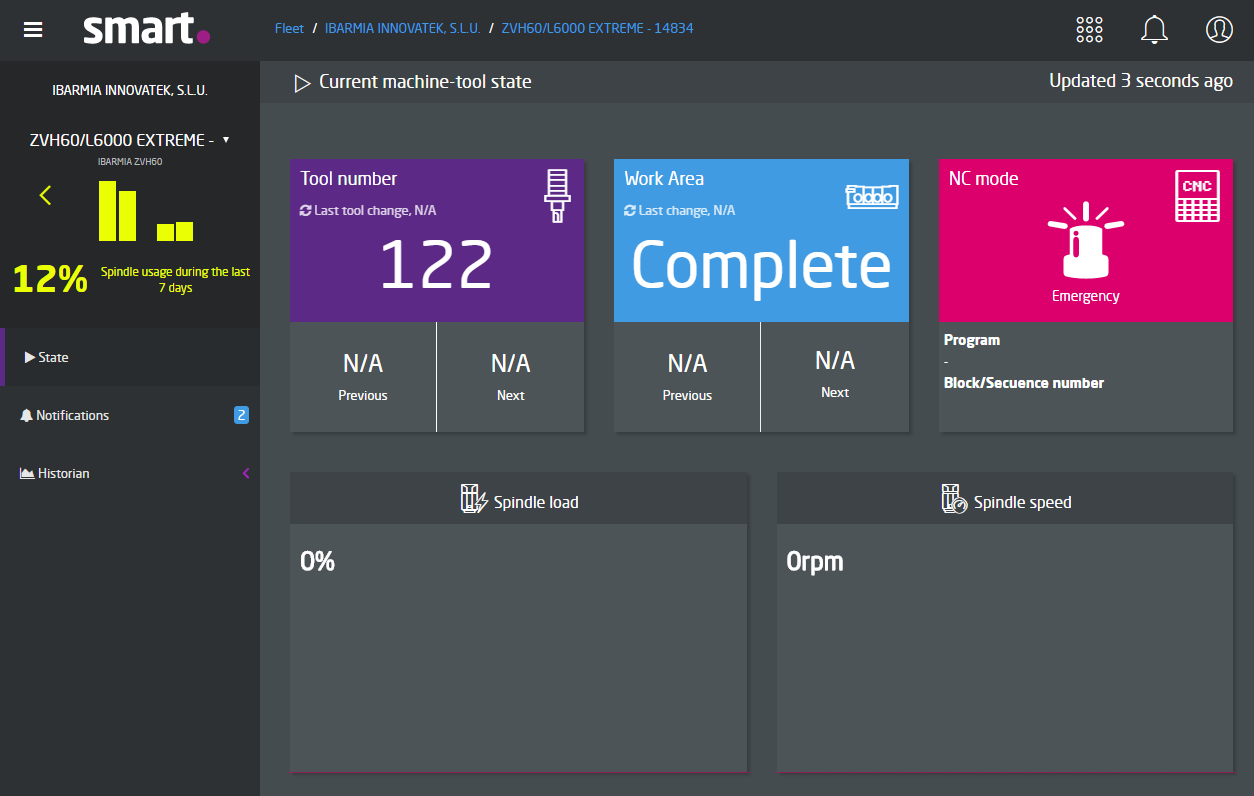

En torno a una máquina existe gran cantidad de información que se puede recopilar y analizar. Qué información registro, con qué frecuencia, dónde la almaceno, para qué la puedo utilizar, cómo la visualizo, en qué formato, en qué entorno,…. Este activo ofrece las respuestas a través de un Generador y almacenador de huellas digitales de máquina y HMI personalizados y multicontrol integrables en el control de la máquina. Generador y almacenador de huellas digitales de máquina (Fingerprint) para monitorización periódica del estado de salud de componentes de máquina, a partir de los valores de variables de CNC y de sensores, obtenidos durante la ejecución de ciclos de chequeo, y comparándolos con los valores que se obtuvieron en la puesta a punto de la máquina. La aplicación de técnicas de minería de datos a los Fingerprints obtenidos a lo largo de la vida de las máquinas, permite establecer nuevos límites de las desviaciones con respecto al patrón de normalidad, y obtener Fingerprints y técnicas de detección de fallos más robustas. HMI personalizados y multicontrol para integración en el control de la máquina. Desarrollo de soluciones de visualización para monitorizar/gestionar datos de Máquina-Herramienta de distintos fabricantes. La solución utiliza tecnologías abiertas HTML5 para generar la interfaz de visualización, de forma que la visualización es aplicable (y reutilizable) en distintos CNC de varios fabricantes (como Heidenhain, Fanuc o Siemens, por ejemplo).

FIELDS OF APPLICATION

Digitalization and Conectivity

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Advanced data acquisition System, XPI, from National Instruments

Advanced data acquisition System, XPI, from National Instruments

-

DAQ standard LabView equipment

DAQ standard LabView equipment

-

IoT equipment and embedded hardware

IoT equipment and embedded hardware

-

Machine-tool numeric controls.

Machine-tool numeric controls.

-

Sensors for the acquisition of signals that make up the machine fingerprint (accelerometers, thermocouples, etc.) and associated electronics.

Sensors for the acquisition of signals that make up the machine fingerprint (accelerometers, thermocouples, etc.) and associated electronics.

SERVICES OFFERED BY THE ASSET

Data visualisation / monitoring

Visualisation of internal CNC data in an HTML5-based interface

Design and implementation of machine-tool fingerprint

Development and implementation of machine-tool fingerprint for the regular monitoring of the health of machine components, based on the values of CNC variables and sensors, obtained during the performance of test cycles and comparing them to the values obtained in the fine-tuning of the machine. Design, development and implementation of the HW and SW required for edge and cloud computing.

Sensoring

Selection and integration of sensors in assets and processes to capture the critical variables as per the aim

Wireless and/or self-powered communication sensors

Development of self-powered sensors with low consumption communicated with data storage platform

ENTITY MANAGING THE ASSET

Contact person:

Karmele Florentino

karmele.florentino@tecnalia.com