NAME Laser ekipamendua fabrikazio gehigarrien bidez sortutako piezen zona konkretuak leuntzeko edo testurizatzeko

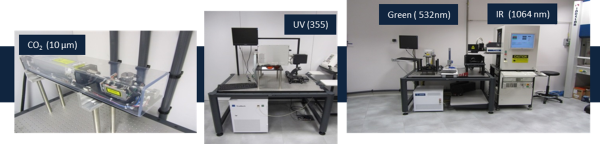

Laser ekipamenduarekin material plastikoz zein metalikoz osatutako piezen zona konkretuak testurizatu edo leundu daitezke. Esaterako, pieza metaliko baten gainazalaren leuntasuna %60 arte jeitsi ahal daiteke. Aktibo hau beste bi aktiboekin (CID.001 eta CID.002) konbinatu ezkero leuntasun murrizketa haundiagoak lor litezke. Potentzia baxuko 4 laser daude (IR, UV, CO2 eta berdea). • CO2 laser (30W) (Easy Mark) • Green laser (7W) (TruMark 3220) • Nd:YAG laser (25W) (Rofin, Power line E25) • UV Laser (5W) (TruMark 6350) LAktibo honek ondorengo ekipamenduekin osatzen da: • Gainazalaren zimurtasuna neurtzeko ekipamendua (gaur egun, off-line motakoa; in-line motako ekipamendua eskuratzeko asmotan). • Gainazalaren karakterizazio osagarria egiteko ekipamendua (termografia, korrosioa, bustitzeko ahalmena, distira, masa galera, piezaren geometria aldaketak, etab.). • Laser ekipamendua kontrolatzeko eta monitorizatzeko software-a eskuratzeko asmoz. Softawe-a MES batekin konekzioa errezteko erabiliko da eta MES-aren bidez pieza fabrikatzeko planta osoa kudeatu ahal izango da. Aktibo hau CIDETEC-ek dituen beste bi aktiboekin (CID.002 eta CID.001) konbinatu ezkero, fabrikazio gehigarriz (AM-z) sortutako piezen post-prozesurako planta oso bat edukitzea ahalbidetzen da eta, gainera, baldintza ezberdinak behar dituzten pieza metalikoak, eta geometria oso desberdinetakoak tratatzeko erabil daiteke (%ko 95erainoko leuntasun murrizketak lor litezke). aser hauek gainazal lauetan edo kurbadura txikiko gainazaletan lana egiteko prestatuta daude.

FIELDS OF APPLICATION

Post process

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

CO2 nanosecond Laser

CO2 nanosecond Laser with a maximum power of 30 W and a focal lens f80 that allow processing areas of 53x53 mm. The equipment works in pulsed mode with a beam size of approximately 100 microns under focusing conditions.

-

Equipment for the evaluation of surface roughness

Equipment for the evaluation of surface roughness (contact profilometer, confocal microscope, AFM) and equipment for additional surface characterization (thermography, wettability, brightness, weight loss, changes in geometry of the piece, corrosion, etc.)

-

Green nanosecond laser

Green nanosecond laser with a maximum power of 7 W and a focal lens f160 that allow to process areas of 110x100 mm. The equipment works in pulsed mode with a beam size of approximately 30 microns under focusing conditions.

-

IR nanosecond laser

IR nanosecond laser with 25 W of maximum power and two focal lenses (f160 and f300) that allow processing areas of 120x120 mm and 240x240 mm. The equipment can work either in pulsed or continuous mode. The approximate beam size in focusing conditions is 40 microns and 70 microns, depending on the focal lens. This equipment is also equipped with software that allows focusing the laser beam over a high range of heights (Fast Focusing Module). It also has a rotary axis of parts.

-

Nanosecond UV Laser

Nanosecond UV Laser with 25 W of maximum power and a focal lens f160 that allow processing areas of 80x80 mm. The equipment works in pulsed mode with a beam size of approximately 35 microns in focusing conditions.

SERVICES OFFERED BY THE ASSET

Advice for scaling and industrial feasibility study

Industrial and technical feasibility studies of the processes developed in this asset

Development and optimization of post-processing of AM parts. Prototype obtaining

Roughness control of selective areas of metallic and plastic parts manufactured by AM with not complex geometries.

Process monitoring and control

Once the monitoring and control software has been acquired, the post-processing plant can be connected to the additive manufacturing processes and will have input on the specific requirements of the part or component to be treated.

Training

Practical and theoretical training in post-processing and surface finishing technologies.

ENTITY MANAGING THE ASSET

Contact person:

Gemma Vara Salazar

gvara@cidetec.es