NAME Funtzionalizazio-unitatea eta gainazaleko tratamendu termikoak ultramotz pultsulaserren eta interferentziaren bidez

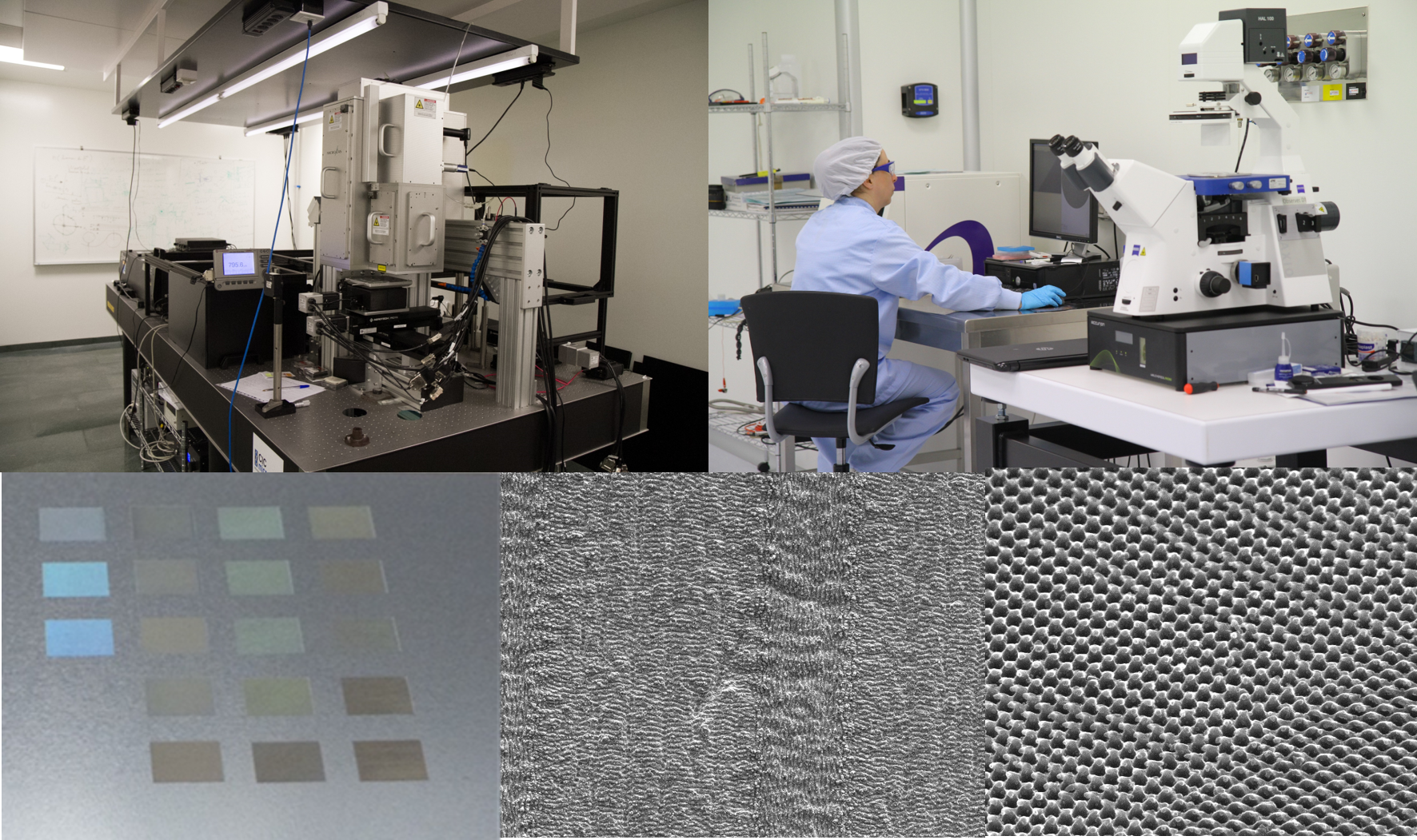

Funtzionalizazio-unitatea bi laserrek osatzen dute, eta horiek prozesu-zerbitzu bateratua ematen dute femtosegundoko laserrekin: 1. Coherent Libra laser bat 3 ardatzeko mekanizazio-estazio batean integratuta. Uhin luzera 800 nm, 400 nm eta 266 nm duten ultramotz pultsuak erabil ditzake. 2. Satsuma Amplitude laser bat 3 ardatzeko estazio eta scanner batean integratuta, 5 ardatz gehitzeko guztira. 1030 nm eta 515 nm-ko ultramotz pultsuak erabil ditzake. Hiru sorta kudeatzeko sistema daude laserra laginera bidaltzeko nahi diren baldintzekin: 1. XYZ mahaietan oinarritutako sistema bat, mikroskopio leiar trukagarriekin. 2. Laser ultralasterretarako bereziki egokitutako sistema galvanometrikoa. 3. Sorta-aniztun interferentzia-sistema bat uhin-luzera baino txikiagoak diren geometriak definitzeko. Unitatea giro garbi batean dago, gela garbiko prozesu mikroelektronikoekin bateragarria. Gainera, gas geldoen atmosfera kontrolatuetan laser prozesuak egiteko gaitasuna du.

FIELDS OF APPLICATION

Coatings and Surfaces solutions

Design and development of materials

Manufacturing processes

Materials and processes in Circular Economy

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

-

Laser Amplitude Satsuma

Laser Amplitude Satsuma

-

Laser interference patterns generation system

Laser interference patterns generation system

-

Laser Libra HE

Laser Libra HE

-

Micromachinig station: 3 axis

Micromachinig station: 3 axis

-

Micromachining station: 5 axiws and beam manangement system

Micromachining station: 5 axiws and beam manangement system

SERVICES OFFERED BY THE ASSET

Deposition of thin and thick films by PVD, CVD and laser..

Deposit of thin / thick films on substrates in order to alter the surface properties or generate new properties. The laser provides an additional activating process on the deposited film. Energy storage (batteries),

Development of surface structuring processes (tens of nanometers to microns)

Physical recording of surface topologies with very high precision for tribological, decorative applications, inserts in injection molds, energy storage, metrology

Generation of embedded microsensors

Generation of transducer structures on the surface of metal parts. For example, diffraction gratings as a thermal sensor that can be interrogated remotely

Processes of micro-machining and micro-cutting with very high precision with femtosecond lasers

Cutting of thin sheets of metals and plastics up to 1mm thick with exceptional precision and arbitrary geometry.

ENTITY MANAGING THE ASSET

Contact person:

Yago Olaizola Izquierdo

yolaizola@ceit.es