Tubispec project: measurement and 3D imaging for quality parameters

Tubos reunidos

DATA DRIVEN SOLUTIONS

Tubos Reunidos is global leader in niche segments of special seamless steel tubular products. Through 120 years of history and presence in more than 100 countries, this company needed to implement a system that would make it possible to extract both inside and outside measurements of the tubes.

Using AI and simulation/interaction tools, they have managed to develop a system for digitising and automatically analysing the geometry of the tubes produced, which first digitises tube specimens to obtain a detailed digital model of their outer and inner surface, and then analyses these models to obtain the quality parameters.

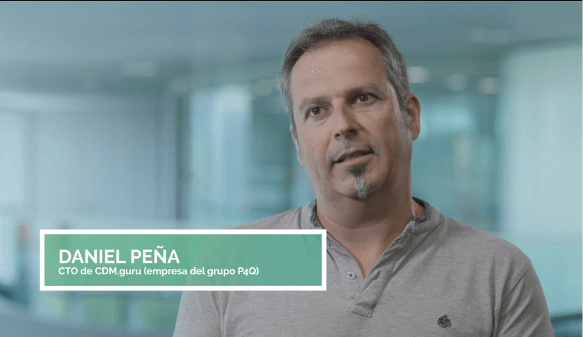

The Tubos Reunidos team tells you all about it!

Need:

El Proyecto Tubispec nace desde el Departamento de Laminación, debido a la necesidad de tener mayor fiabilidad de las mediciones que se hacen de los tubos, previamente realizadas a mano. Digitalización de la probeta y obtención de una imagen 3D de la superficie interior y exterior del tubo a través de un análisis geométrico.

Area of the company where the solution is focused:

Oil, Petrochemical, Mechanic Installation

Company size:

PYMESector:

Oil, Petrochemical, Mechanic InstallationLocation:

Bilbao (Bizkaia)Benefits of the Solution:

- Agile and faster measures for efficient interventions in the hot roll process.

- Measurement data of the whole tube and other parameters such as roughness or eccentricity.

Incorporated Technologies:

- IA

- Simulation and interaction tools