Cell for research on large size parts grinding

DESCRIPTION

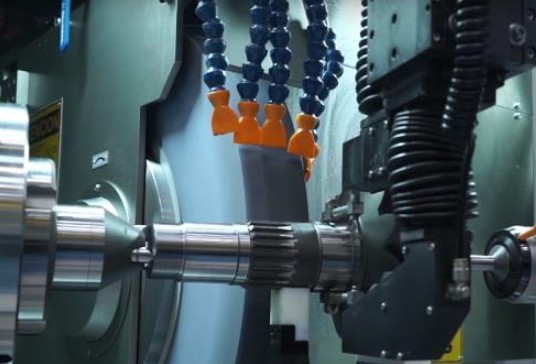

Cell for research and development acrivities in high-performance grinding processes for medium-large dimension pieces with high added value in sectors such as aeronautics, railways and energy. Composed by a horizontal cylindrical grinding machine equipped with a double rotating head, a multidiameter measuring system with high flexibility and precision. A second machine in the cell is a vertical multitasking cylindrical grinding machine, with capacity for hard turning, cylindrical grinding of inner and outer diameters and face grinding, as well as an in-process measurement system. The cell is completed with a mobile column multitasking machine with capacities for milling, turning and grinding, equipped with a robotic magazine with up to 150 tools.

The cell is completely monitored for the measurement of vibrations, forces, temperatures, in addition to the working parameters. This monitoring data are transferred to the cloud platform from which the monitoring parameters are processed and analyzed, and is complemented by simulation models of the behavior of the three units that compose it. The operation of the three units is carried out through a specific proprietary HMI for grinding.

The cell is also equipped with systems for non-destructive inspection (NDT) through ultrasonic, eddy current and active thermography technologies. It has the ability to design specific sensors for applications and parts of interest, so that in addition to standard verification of the results of the processes studied and the rectified parts, customized solutions can be developed and tested.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

DANOBAT HG72-3000 grinding machineMedium to large size cylindrical grinding machines, equipped with double wheel tilting headset and a multidiemeter integrated measuring system.

Multitasking Cylindrical vertical grinding machine, with capacity for hard turning, cylindrical ID - OD and face grinding, in addition to an in-process measurement system

DoGrind programming software specific for general purpose and also special grinding cycles (shapes, curvics).

Equipment for verification of surface integrity, thermal damage and residual stresses through Ultrasound, Eddy Current and Active Thermography

Travelling column multitasking machine with capacities for milling, turning and grinding, equipped with a robotized tool magazine of 150 tools. The machine is also equipped with the DAS+ active damper for maximum cutting capability and adaptive process.

SERVICES OFFERED BY THE ASSET

Research on new grinding processes and special grinding cycles

Research on the behavior of new advanced components: grinding wheels, cooling systems, measurement systems, special heads, dressing systems

Tests on special production conditions for particular parts

Training and updating of specialists

ENTITY MANAGING THE ASSET

IDEKO S.C.

Contact person: RAFA LIZARRALDE