Bioprinting Laboratory

DESCRIPTION

Laboratory with equipment for the design, development and characterisation of bioinks and for the bioprinting of scaffolds, organs and tissues and for the evaluation of three-dimensional structures for tissue engineering and regenerative medicine.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

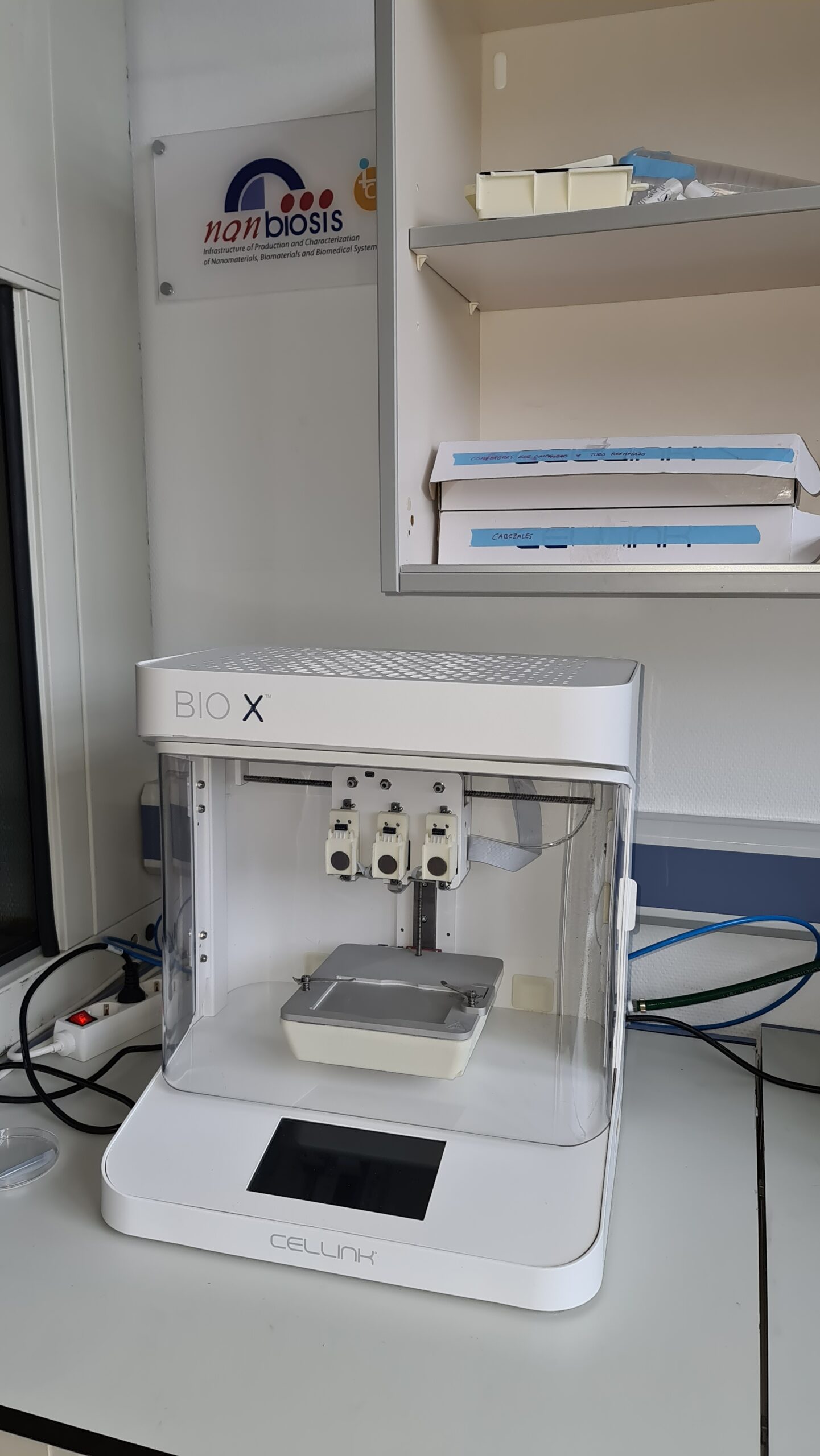

Bio X Bioprinter (Cellink brand)Bio X Bioprinter (Cellink brand). Bioprinter for tissue engineering, drug discovery, toxicity research, and to make 3D cell culture faster.

Technical characteristics:

Three printhead assemblies compatible with CELLINK smart printheads, including. Standard pneumatic print head

Electromagnetic droplet print head

Temperature-controlled pneumatic print head

Syringe pump print head

Thermoplastic print head

Temperature controlled printer (4 C to 60 C)

Clean chamber technology with UV-C germicidal lamps and double HEPA H14 filter system

Interchangeable light curing modules

365 nm and 405 nm

The 4 cell culture ovens incorporate a series of internal systems, processes and design factors that work together to maintain a multi-layered defence against contamination in the in vitro environment. The integration of a safe and effective two-hour sterilisation process, the fastest in the industry, provides total sterilisation of all interior surfaces and returns to service faster than conventional incubators using high heat sterilisation. As a result, the SANYO incubator can be used for a wider range of cell culture applications, including the most highly regulated protocols in the industry.

Nano DSC (TA Instruments) The Nano DSC differential scanning calorimeter is designed to characterise the molecular stability of dilute biomolecules in solutions.

The Regemat 3D printer in the pharmaceutical industry allows the development of controlled release of drugs, development of multi-component tablets, customised controlled release of drugs, development of lab-on-a-chip and organ-on-a-chip for drug testing, trilaminar skin printing to test transfers that occur between the different layers of the skin when applying creams or for cosmetics testing, cosmetics testing, microbiological systems and drug toxicity detection.

Texture analysis is the mechanical testing of cosmetics, pharmaceuticals, biogels, cosmetics, adhesives and other products to measure their physical properties.

Due to its adaptability, texture analysis has become commonplace in many industries to measure a number of specific characteristics or properties related to the way a material behaves, breaks, flows, sticks, bends, etc.

SERVICES OFFERED BY THE ASSET

Bioink development

Development of Scaffolds

ENTITY MANAGING THE ASSET

UPV/EHU

Contact person: Gorka Artola Beobide