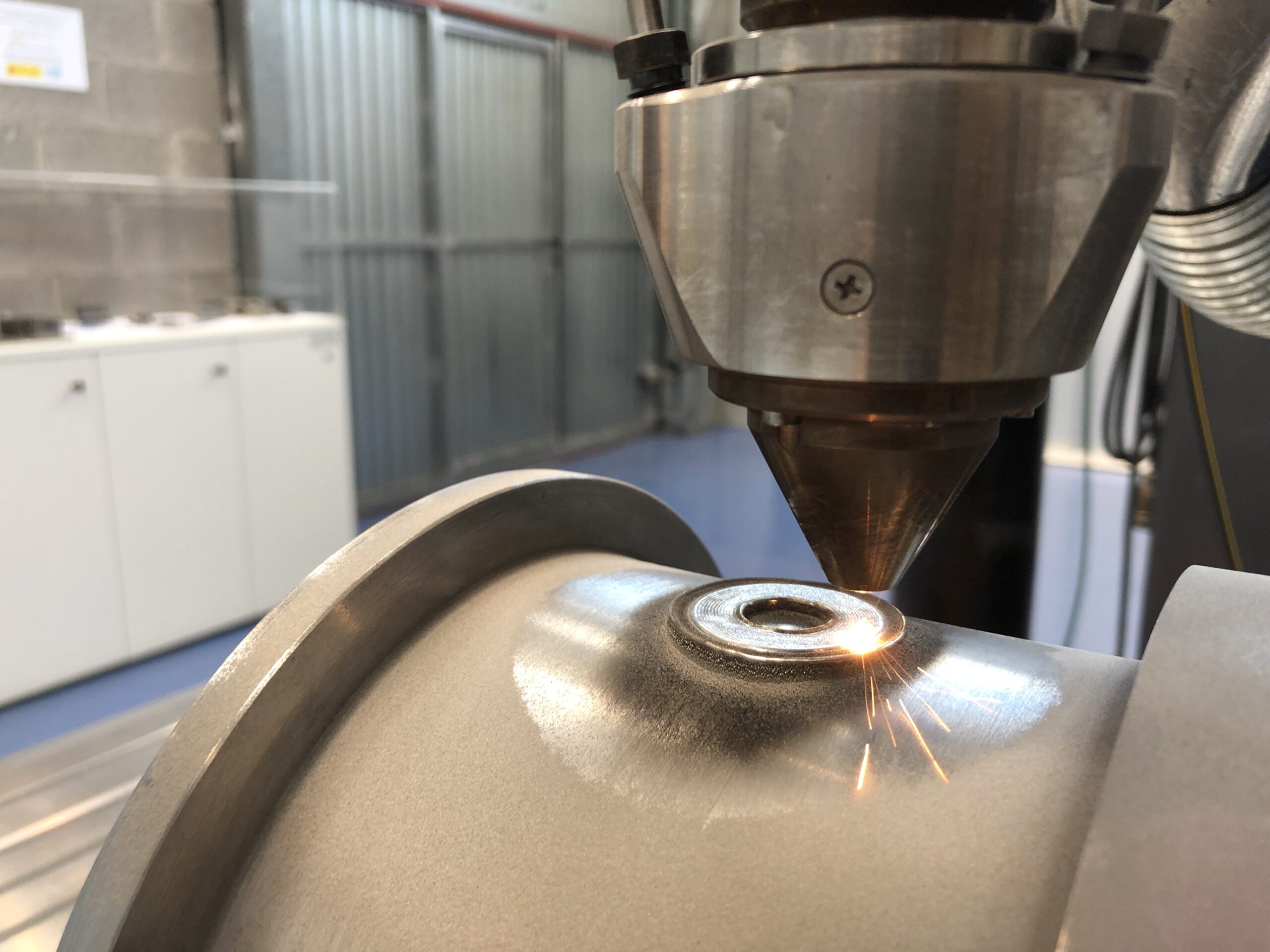

Multi-material robotic and Cartesian flexible additive manufacturing cell by directed energy deposition laser beam DED-LB (LMD) powder

DESCRIPTION

Directed Energy Deposition-Laser Beam, or LMD, for the development, in different flexible machine architectures, of new materials, processes, monitoring, control and simulation, in order to offer repair and manufacturing solutions for the industry:

- Manufacturing by direct deposition of metal powder, and fusion using a laser beam.

- Optimization of processing parameters.

- New base alloys Fe, Co, Al or Ni for applications at high temperature and/or resistant to wear and mechanical fatigue.

- Short series, personalized pieces. Repair of high value parts.

- Implementation of multivariate control process strategies.

- Development of solutions, components with new functionalities: more efficient designs, multi-material, components with property gradients, etc.

- Digitalization of DED processes in industrial production.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

KINEMATIC STATIONSCNC Fagor 8070

Robot (KUKA, FANUC, ABB)

Gantry

2-axis positioners

Rotating tables

Disk, Diode, Nd:YAG and Fiber laser sources (up to 6kW) fiber guided

Different optical heads: Trumpf BEO-D70-0º, BEO-D70-90º, BEO-D70M (Spot Laser 1-4mm)

Coaxial and discrete nozzles: COAX40; COAX50, HigNo4.0 y discrete 3-Jet

SERVICES OFFERED BY THE ASSET

ENTITY MANAGING THE ASSET

LORTEK S.C.

Contact person: Maitane Ipiñazar