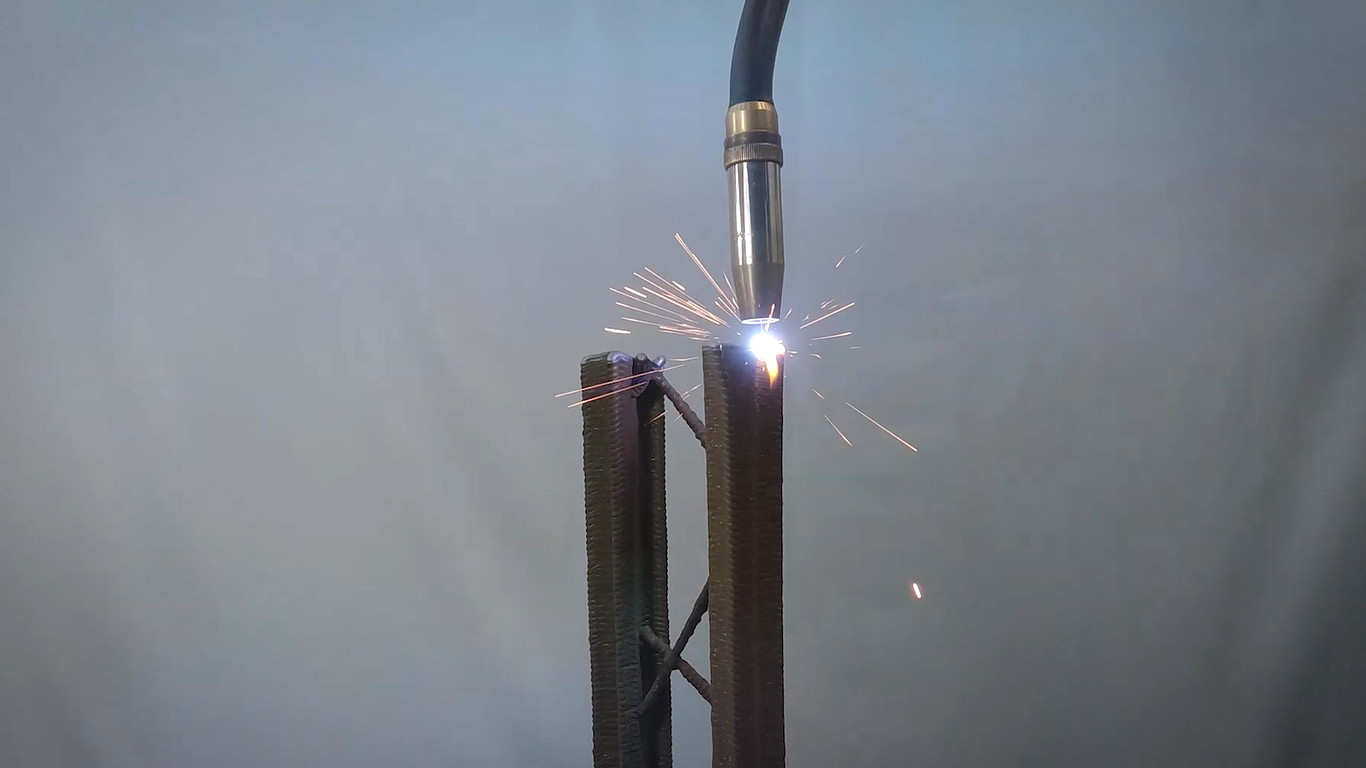

Additive Manufacturing Robotic Cell based on High Deposition Rate by directed energy deposition with electric arc and wire DED-ARC (WAAM)

DESCRIPTION

Design and development of DED-Arc (Directed Energy Deposition -Arc) systems and processes, or WAAM, for repair, hybrid manufactruing or manufacturing of large format components and/or preforms, supported by digital solutions aimed at ensuring the part quality of the manufactured products.

Development of new WAAM processes with higher deposition rates through the incorporation of multi-wire arc technologies (e.g., CMT TWIN and ) and hot wire technologies (e.g., TIGSpeed, EWM MIG/MAG hot wire).

Development of new in-situ alloys for WAAM.

Development of advanced deposition strategies that allow reducing the necessary machining allowances and minimizing residual stresses and geometry distortions of the manufactured parts.

Optimization of the heat treatments necessary after manufacturing to achieve a good balance of properties and eliminate residual stresses.

Research in process monitoring and process control technologies for early detection of isolated defects (porosities, lack of fusion).

Research in non-destructive inspection technologies (ultrasound, radiography, tomography) for the detection of defects.

Process simulation and CAD/CAM/CAE tools for the automatic manufacturing of large parts in 2.5D and 3D.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

CINEMATIC STATIONSCNC, Robot (KUKA, FANUC, ABB), Gantry and 2-axis positioners and rotary tables.

CMT, CMT Twin, TIG, plasma, EWM MIG/MAG.

SERVICES OFFERED BY THE ASSET

ENTITY MANAGING THE ASSET

LORTEK S.C.

Contact person: Maitane Ipiñazar