Design and characterization of steels

DESCRIPTION

Specialized asset on the design and characterization of low-alloyed steels including steelmaking manufacturing processes and in-use product properties. Services include design and manufacturing of experimental casts, determination of transformation temperatures, CCT/TTT diagrams, design of thermal treatments, assessment of hot and warm deformation properties, analysis of microstructure by SEM and LOM and fatigue testing.

Team expertise in steel processing (steelmaking and downstream) and properties along the value chain

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

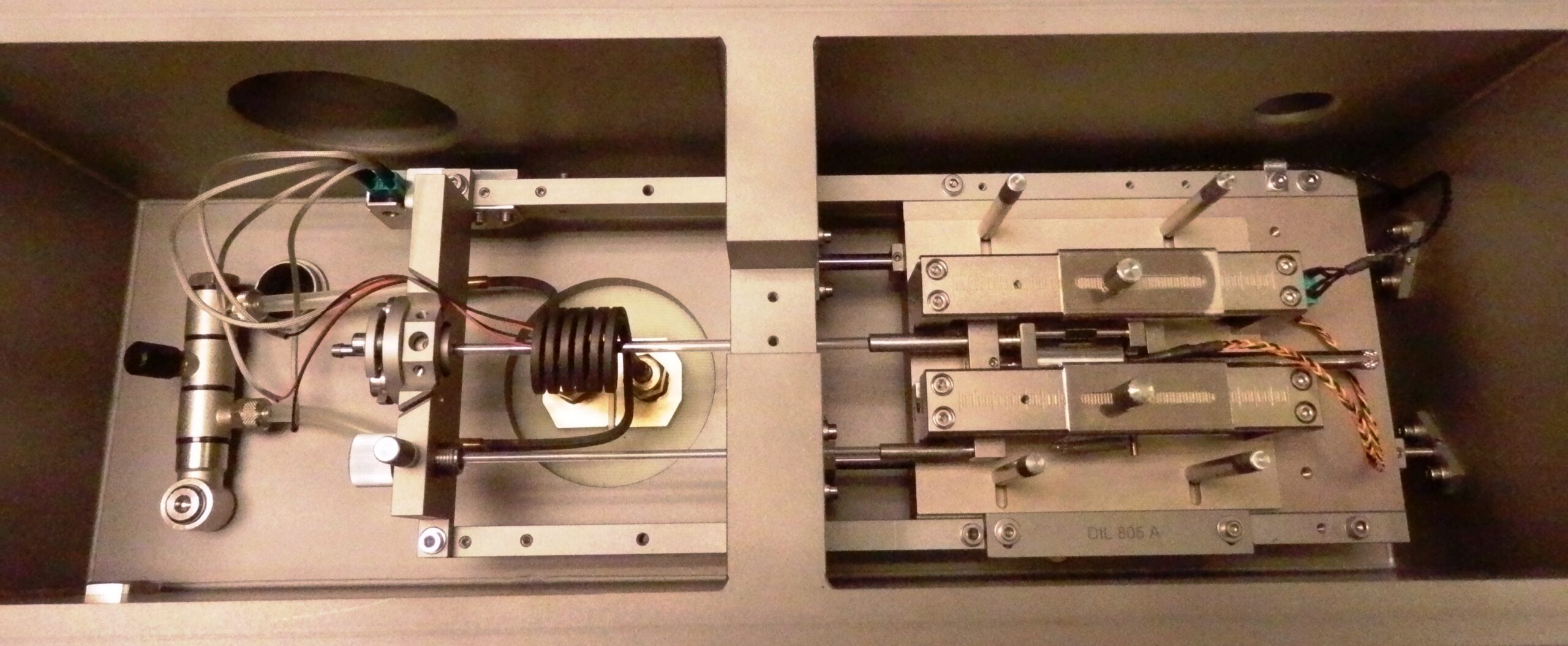

Dilatometer BÄHR DIL805LExperimental facility for the measurement of steel transformation temperatures on heating (Ac1 and Ac3) and the measurement of the steel transformation temperatures on cooling for different cooling rates and procurement of CCT and TTT diagrams.

Experimental simulation of thermal treatments for any steel grade.

Fatigue machine for the experimental determination of the S-N Wöhler curve of steels for a particular heat treatment condition under alternating or push-pull axial loading.

Fatigue testing can be done at different temperatures (from -20ºC to 500ºC) thanks to a climatic chamber. Further analysis of fatigue failures and root causes.

Scanning Electron Microscope (magnification x1000000, topographical and compositional image, EDS analysis, EBSD and automatic image analysis) for the characterization of steel samples, analysis of failures of mechanical components and technological advice and assistance on metallurgical processes and products.

Equipment for physical simulation of thermomechanical processes, analysis of hot and warm forgeability, assessment of steel hot ductility, forging stress-strain curves. It is suitable for the experimental simulation of hot forging and hot rolling processes and further estimation of properties in as-forged condition.

Melting furnace for the manufacturing of commercial and/or new developed steel grades. 40-kg ingots of defined chemical composition can be fabricated in a vacuum induction furnace for further characterization and comparison with standard grades and procedures.

SERVICES OFFERED BY THE ASSET

Design and manufacturing of experimental casts

Determination of critical transformation temperatures of steels

Estimation of Hot and Warm deformation properties

Fatigue characterization of steels

Microstructural analysis and failure analysis

ENTITY MANAGING THE ASSET

SIDENOR INVESTIGACIÓN Y DESARROLLO, S.A.

Contact person: Roberto Elvira Eguizabal