Inspection/measurement robotic cell using non-destructive techniques

DESCRIPTION

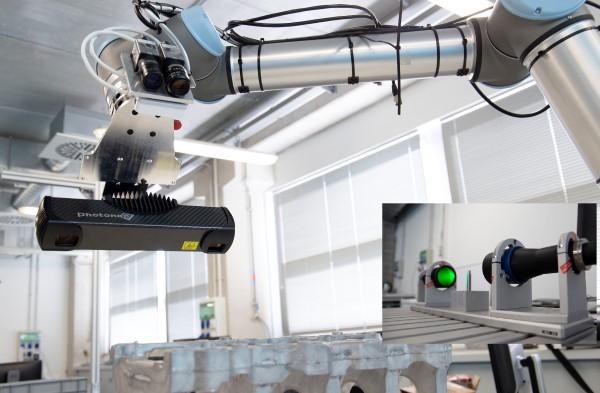

The cell allows the analysis for quality control and non-destructive inspection of parts. The system can be configured to perform inspection and measurement operations using various technologies including robotic arms, vision cameras, thermography, multispectral and different types of processing algorithms of the images obtained. The system consists of 2D or 3D vision systems, stereo photogrammetry, non-destructive inspection equipment (multispectral, thermography), and infrastructure to simulate different configurations and working conditions in the piece. The inspection systems are configurable for use in various functions. The cell allows to perform different studies on a piece:

• 2D / 3D dimensional control using 2D and 3D vision techniques;

• Detection and identification of surface defects.

This cell offers the possibility of evaluating the feasibility of carrying out inspections both in-line and off-line, analyzing requirements linked to resolution, cycle times, etc. and automate solutions for both quality control and piece handling.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Configurable 2D / 3D vision systemGocator camera, Ranger Sick, IAI photometric stereo equipment, Pulsix Multispectral Equipment, Thermal camera

SERVICES OFFERED BY THE ASSET

Demonstration / Approaching technology

Proof of concept

Technical feasibility analysis

Training

ENTITY MANAGING THE ASSET

FUNDACIÓN TEKNIKER

Contact person: Ander Ansuategi