SMART: This asset compiles a series of applications in different fields which provide the machine with advanced features and contribute to a diagnosis and in some cases, intelligence-based action.

DESCRIPTION

SMART: This asset compiles a series of applications in different fields, such as:

Thermal optimisation: Characterisation of the thermal performance of machines based on tests in sensorised machine, thermal modelling of machines using advanced thermal FEM, design of thermoset machines, monitoring and recording of thermal performance of machines, development and implementation of control functions for on-line offsetting of thermal deflections.

Advanced control functions: Development and integration of advanced machine functions based on control parameters and embedded sensors to strengthen the machine’s process, protection and safety features and help the user’s operability: balanced, self-adjustment of axes, protection of heads, detection of abnormal vibrations, process monitoring, etc.

Integration of sensors in critical components: Design and integration of sensorised machine components, aimed at improving the machine’s features and safety and supporting the manufacturing process: heads with integrated accelerometers, screws with temperature sensors and accelerometers, machine structures with displacement sensors, etc. Development of HW and the necessary SW to offer comprehensive solutions, fully integrated in the machine and their control.

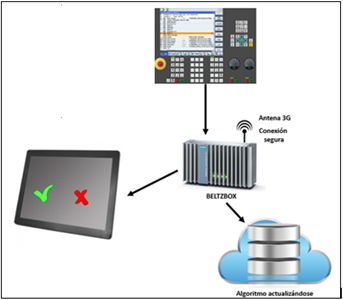

On-line supervision of manufacturing process: on-line information, based on CNC signals and sensors, related to whether a machining process is taking place within the admitted parameters, based on previously defined normality models through the data records for a specific part/process.

Optimisation of tool lifetime: prediction of the remaining life of cutting tools for machining processes based on the capture of CNC and sensor signals, issuing a continuous diagnosis of the remaining use time or the number of parts that a tool will be able to machine.

Process quality control: 3D vision camera using structured light technology integrated in the machine. Thanks to the detection, location and comparison SW, the quality of the finished part is controlled, whereby the user may define corrective actions. The suitability of the initial part to the CAD of the target part can also be controlled prior to the process.

These applications provide the machine with advanced features and contribute to a diagnosis and, in some cases, intelligence-based action.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

CNC controls for the development of thermal deflection offsetting functions through the control of machine-tools.CNC controls for the development of thermal deflection offsetting functions through the control of machine-tools.

Sensors for integration in machine components (accelerometers, thermocouples, LVDTs, etc.) and associated electronics.

Software for the calculation of thermal performance by finite elements: MSC MARC

Thermal testing measurement equipment: displacement, temperature, level sensors, etc.

Vibration acquisition and processing equipment

SERVICES OFFERED BY THE ASSET

Advising

Balance solution for machine-tool dividers

Characterisation of the thermal performance of machines through testing

Control functions to offset the machine’s thermal deflections

Design of thermoset machines

Design, integration and processing of sensorised machine-tool components

Integration of camera in the machine for control of the initial part and CAD.

Integration of camera in the machine for quality control

Modelling, characterisation and thermal optimisation of machines by finite elements

Monitoring and protection of machine-tool heads

Optimisation of tool lifetime

Research into manufacturing processes (machining) to generate models that enable their status to be controlled in real time.

Sensing of ball screws and signal processing

ENTITY MANAGING THE ASSET

FUNDACIÓN TECNALIA RESEARCH & INNOVATION

Contact person: Karmele Florentino