Structural Integrity Unit

DESCRIPTION

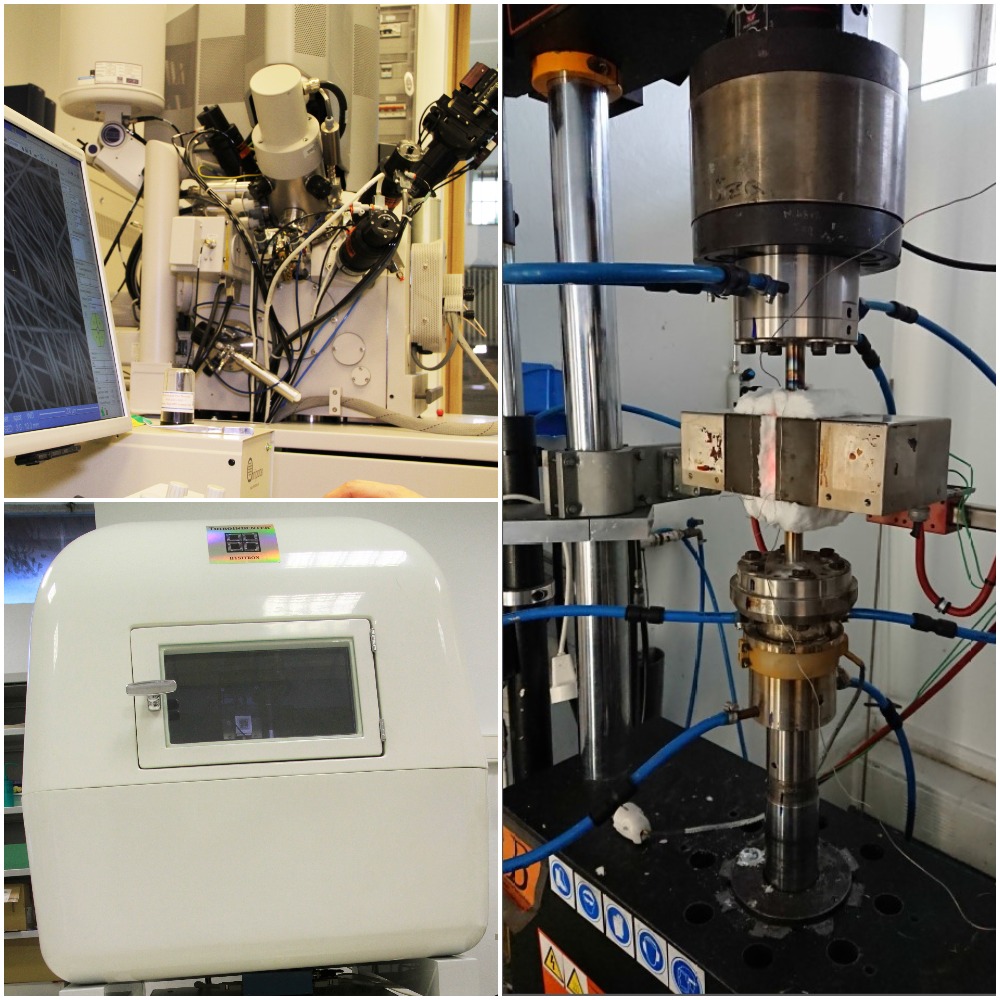

The unit combines a complete testing equipment for the mechanical characterization of materials and components and the expertise to extract meaningful information from the tests. Testing includes dynamic loadings from very small strain rates (1 µm/hour, typical of creep at elevated temperatures), up to 14 m/s (impact tests). Testing frequencies range from 1 cycle in several minutes (thermo-mechanical fatigue tests) to 200 Hz (in resonant fatigue testing machines).

Loading can be uniaxial (tension-compression) or biaxial (tension-compression plus torsion), within a temperature ranging from liquid nitrogen (77 K) up to 1200 °C. Strains are measured (measuring hysteresis loops) at all temperatures and environments. Fatigue limit and complete S-N (stress vs. number of cycles or time) curves can be determined for real materials, components and structures.

Artificial micro-defects can be introduced by Focused Ion Beam (FIB) milling, when required on testing samples. Interfaces between different materials (surface depositions, coatings) can be characterized determining bonding energy and interface toughness. Early crack detection is available through Infrared Thermography with a resolution of 10 µm.

Residual and total life assessment are deduced, including effects of local residual stresses. Residual stresses are obtained by x-ray diffraction. Local residual stresses are measured -by FIB and Digital Image Correlation (DIC)- at the microscale level.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Electromechanical fatigue testing machine (1 µm/h), Instron 8562Electromechanical fatigue testing machine (1 µm/h), Instron 8562

Focused Ion Beam (FIB) milling. Quanta 3D FEG

Nano-indenter & TriboIndenter

Servo-hydraulic fatigue testing machine, Instron, ± 250 kN

Servo-hydraulic tension-torsion fatigue testing machine, Instron 8874

SERVICES OFFERED BY THE ASSET

Characterization of Interfaces

Forensic failure analysis

Life assessment

Measurement of mechanical properties

ENTITY MANAGING THE ASSET

CEIT

Contact person: Asier Bergara Arregui