Unit of functionalization and surface treatments using ultrashort pulse lasers and interference

DESCRIPTION

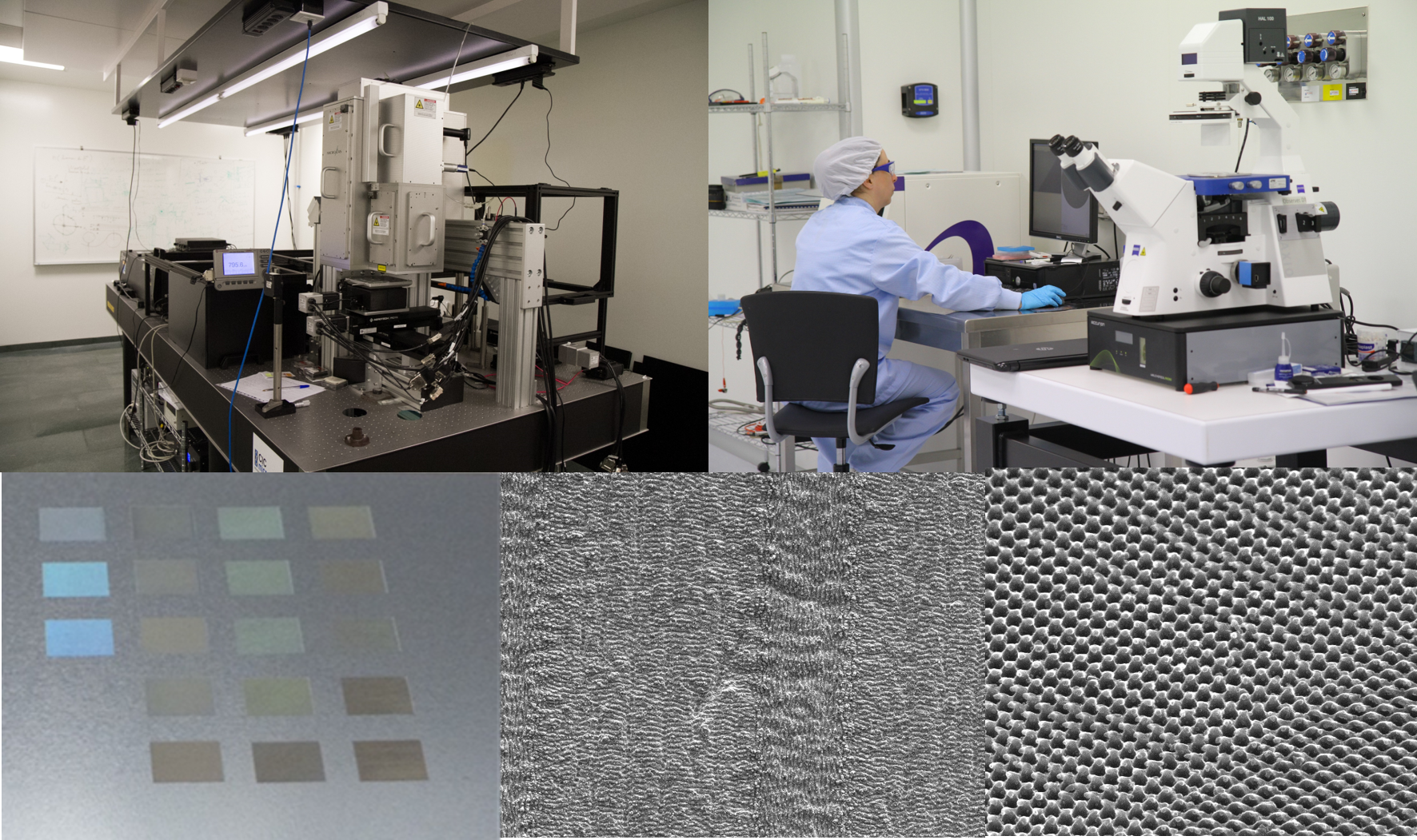

The equipment of the unit of laser surface functionalisation comprises two lasers that gives a joint service of ultra precise surface processes with femtosecond lasers:

1. A Coherent Libra HE laser integrated into a 3-axis machining station. It can deliver ultrashort pulses of wavelength 800nm, 400nm and 266nm.

2. A Satsuma Amplitude laser integrated in a 3-axis station and scanner, for a total of 5 axes. It can deliver ultrashort pulses of 1030nm and 515nm.

Three different beam management systems are available to send the laser to the sample with the desired conditions:

1. A system based on XYZ tables with interchangeable microscope lenses.

2. A galvanometric system specially adapted for ultra-fast lasers.

3. A multi-beam interference system to define geometries smaller than the wavelength.

The unit is placed in a clean environment compatible with clean room microelectronic processes.

In addition, the unit has the ability to perform laser processes in controlled atmospheres of inert gases.

MOST OUTSTANDING EQUIPMENT AND COMPONENTS

Laser Amplitude SatsumaLaser Amplitude Satsuma

Laser interference patterns generation system

Laser Libra HE

Micromachinig station: 3 axis

Micromachining station: 5 axiws and beam manangement system

SERVICES OFFERED BY THE ASSET

Deposition of thin and thick films by PVD, CVD and laser..

Development of surface structuring processes (tens of nanometers to microns)

Generation of embedded microsensors

Processes of micro-machining and micro-cutting with very high precision with femtosecond lasers

ENTITY MANAGING THE ASSET

CEIT

Contact person: Yago Olaizola Izquierdo